- December 17, 2024

- Posted by: MCAM Northwest

- Category: CAM Assist

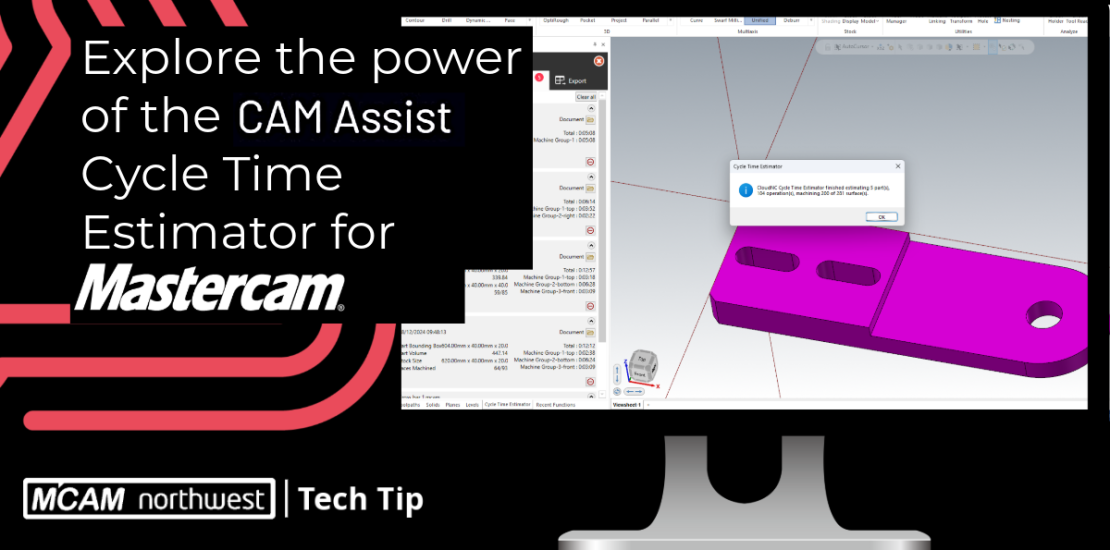

Streamlining Your Workflow with the CAM Assist Cycle Time Estimator

Spend less time programming and more time producing! With CAM Assist’s Cycle Time Estimator, automate toolpath generation and cycle time calculations for multiple parts in minutes—streamlining your workflow like never before.

This tool integrates advanced automation capabilities to simplify complex tasks, saving both time and effort. Whether you are programming for a few parts or an entire production run, this feature automates toolpath generation, cycle time estimation, and shop scheduling preparation in a few intuitive steps.

How can the CAM Assist Cycle Time Estimator improve CNC programming efficiency?

The CAM Assist Cycle Time Estimator automates toolpath generation and cycle time calculations, with options to factor in machine variables like acceleration, tool changes, and setup times. It saves results as a CSV for scheduling and quoting while reducing programmer workload, streamlining CNC workflows and boosting efficiency.

Transform Your Programming Efficiency

Using the Cycle Time Estimator, you can automate the process of generating toolpaths and estimating cycle times for multiple parts. With just a few clicks, the tool calculates detailed cycle times by factoring in variables such as machine acceleration, tool changes, setup times, and part quantities. The generated results are saved as a comprehensive CSV file, perfect for integrating into your shop’s scheduling or quoting processes.

This feature also saves the generated toolpaths directly to the part files, significantly reducing the workload for CNC programmers. By automating this foundational programming step, it allows programmers to focus on refining and customizing the generated toolpaths for production-ready precision.

A Real-World Example

Imagine working with a set of five parts that share common material and machining approaches. Using the Cycle Time Estimator, you can define the tool library, stock material, and machining mode, and then run the automation. In minutes, the tool processes each part, generates toolpaths, and provides an accurate cycle time estimate.

For added flexibility, you can fine-tune the results by applying scale factors for machine acceleration, setting tool change times, and accounting for setup durations. Once these adjustments are made, export the results into a user-friendly CSV format. This file is versatile enough to be processed through software like Excel or other tools for further analysis or scheduling.

The most exciting part? Each part file is already programmed and ready for final adjustments. This ensures that the time saved in the programming phase translates directly into faster production readiness.

Boost Quoting and Scheduling Accuracy in Your Shop

The CAM Assist Cycle Time Estimator is more than just a time-saver; it’s a game-changer for CNC programming. Automating essential programming tasks and delivering actionable insights helps shops optimize efficiency, improve scheduling accuracy, and reduce bottlenecks. Whether you are looking to streamline quoting processes or enhance programming productivity, this tool is a must-have for modern manufacturing operations.

Ready to see how this innovative feature can transform your workflow? Reach out to MCAM Northwest at (503) 653-5332 or contact our Sales Team for a customized demo with your parts. Let us help you take your programming to the next level!

CAM Assist Cycle Time Estimator Key takeaways (TL;DR)

- Automated Efficiency: The CAM Assist Cycle Time Estimator generates toolpaths and calculates cycle times for multiple parts in minutes, saving significant programming time.

- Accurate Estimation: It factors in machine acceleration, tool changes, setup times, and part quantities to provide precise cycle time estimates.

- Streamlined Workflow: Results are saved as a detailed CSV for seamless integration into scheduling or quoting processes, while pre-programmed part files reduce programmer workload.

- Enhanced Productivity: By automating repetitive tasks, the tool frees up programmers to focus on refining toolpaths, accelerating production readiness, and improving shop efficiency.

Follow MCAM Northwest!

LinkedIn: mcam-northwest

YouTube: The MCAM Northwest

Facebook: @MCAMNorthwest

X (formerly Twitter): @MCAM_NW