ANSYS Discovery

THE FIRST SIMULATION-DRIVEN DESIGN TOOL COMBINING INSTANT PHYSICS SIMULATION, HIGH FIDELITY SIMULATION AND INTERACTIVE GEOMETRY MODELING IN A SINGLE, EASY-TO-USE EXPERIENCE.

Easy-to-use Interface

High Fidelity Simulation Powered by Ansys Solvers

Embedded Metaphysics Simulation

First-of-its-kind Live Physics Simulation

Upfront Simulation Speeds the Innovation of Product Design

By answering critical design questions early in the process, thus decreasing engineer labor and physical prototyping costs, Ansys Discovery allows for an ROI boost across your organization. Upfront simulation reduces prototyping and testing needs and minimizes engineering change orders while maximizing design and ideation focus.

Ansys Discovery 3D product simulation software allows engineers to quickly prepare models for simulation or create design variations, all while rapidly exploring multiple design concepts with real-time interactivity. Upfront simulation improves product insight and leads to a more efficient and higher-performing outcome.

Key Features

Simplify your 3D modeling and simulation tasks with a range of Discovery software capabilities.

Key Features

With the interactive nature of Ansys Discovery, engineers can test several design ideas in mere seconds, receiving immediate insights on the structural performance of a design. Expect to quickly observe the different modes of vibration and receive a rapid understanding of resonant frequencies. Discovery removes barriers that previously prevented engineers from using engineering simulation. Instead of dealing with the difficulty of performing structural analyses on complicated geometry, Discovery enables near-instant simulation results once loads are established.

Whether you’re addressing internal or external flow, you can explore a variety of fluid wonders. Incorporate porous media into your analysis when applicable. When you’re ready for additional detail and higher accuracy, use the Ansys Fluent solver within the Discovery environment, without changing your model or your workflow.

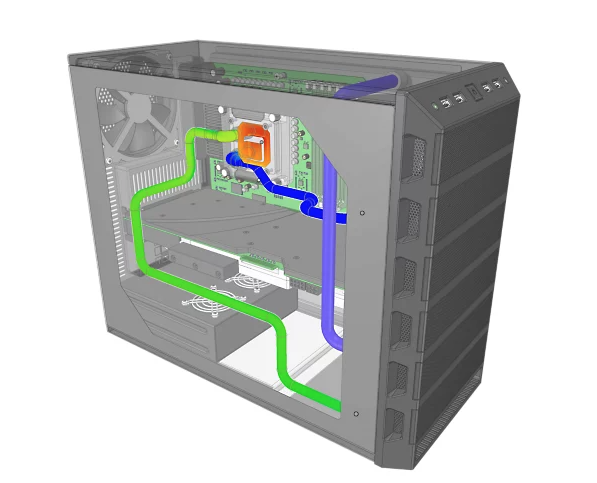

The real-time heat flow and temperature distribution information enables you to test ideas in real time, iterating and ideating along the way to find the best solution for your design needs. Leverage conjugate heat transfer (CHT) to determine fluid and solid temperatures for evaluating fluid and thermal performance of product designs. Solve a wide range of product design challenges with multiphysics simulation capabilities across numerous industry applications.

ANSYS Discovery Overview

Want to learn more about Ansys Discovery? Click here to read the Product Spotlight blog!

Want to learn more about Ansys Discovery? Click here to read the Product Spotlight blog!

ANSYS Spaceclaim

MULTIPURPOSE 3D MODELING, DESIGN, MANUFACTURING, REVERSE ENGINEERING, 3D PRINTING AND SIMULATION PREPARATION.

SpaceClaim is the fastest solid modeler available, letting you process more ideas more quickly and interact directly with your customers. Save time and get the job done right the first time.

Only SpaceClaim has Pull, Move, Fill, and Combine, the easiest way to do 3D modeling with solids. Achieve a higher rate of success with 3D modeling.

Never experience rebuild errors or struggle with complicated constraints. Leave those problems with traditional CAD and use SpaceClaim to reduce errors.

SpaceClaim’s automated repair tools are designed to target problem areas of any model and provide instant options for healing and repair. Whether a model is full of holes, gaps or corrupt surfaces, these tools quickly recreate models to their intended state. Spellcheck-like tools provide feedback on location and possible remedies, but you always have the option of accepting automated repairs or providing further control of surface contours or repair types. The end result is clean surfaces and watertight solids.

NEW PERFORMANCE ADVANTAGES WITH ANSYS SPACECLAIM

Key Features

Engineers who aren’t CAD specialists — and don’t want to be — can learn SpaceClaim in hours instead of weeks. SpaceClaim is the best solution to help increase productivity and to get your CAD/CAM projects completed more smoothly.

SpaceClaim’s automated repair tools are ideal for turning corrupt or incomplete data to usable surfaces or solids for downstream CNC use. Disjointed surfaces, holes and gaps can be automatically healed.

You’ll find SpaceClaim is full of dedicated tools that propel your efforts in the extracting or preparing of geometry needed for any manufacturing application. The versatile tools of this software let you rapidly extract geometry necessary for fixturing or tooling any objects, constructing solids or even extending surface edges.

Key Features:

- Open, edit, and prepare parts from any CAD system

- Easily convert DXF/DWG files into 3D data for machining

- Jig, fixture, tooling, and mold design

- Optimize models by editing rounds, chamfers, hole sizes, and draft angles

- Integrated standard parts from Traceparts or Cadenas libraries

- Leverage strategic partnerships with CAM providers like Mastercam, GibbsCAM, Espirit, MecSoft Corporation, and SigmaTEK

Our vision from the beginning was to bring 3D to everyone by providing a simple, fast, flexible design tool. We believe a 3D tool should be so simple, anyone can learn it quickly and have fun while doing so. SpaceClaim is a fully functioning CAD tool that is powerful enough for rapid concept modeling but is equally as simple for creating detailed parts, assemblies and drawings.

You can Imagine, design, make and realize your ideas faster with Ansys SpaceClaim.

SpaceClaim makes it fast and easy to transition from popular 2D data types to 3D geometry. Whether you only have a graphics image or a sloppy 2D drawing, SpaceClaim lets you work in the context of what you have to construct precise 3D geometry. If you can start with a precise drawing, half the work of going from 2D to 3D is already done for you. SpaceClaim supports file types such as DXF, DWG, bitmaps, jpg, and png, and uses common workflows for the reconstruction to 3D data. If 2-D data is corrupt or incomplete, automated tools will heal the data so it is 3D ready.

SpaceClaim enables you to easily visualize, communicate, and evaluate designs in 3D in order to achieve new levels of innovation through product design and development. Whether a non-CAD expert or seasoned CAD professional, the SpaceClaim user interface allows you to refine and optimize concept models before locking down the design in a traditional CAD package.

While traditional/history based modeling tools are important to ensure successful production, the constraints used in these tools become troublesome for the initial concept design phase of product development. SpaceClaim frees you from the constraints of history-based concept modeling, allowing you to focus on the creative process and not on the technology. With an expanded use of 3D in this early modeling phase as well as throughout the entire product design and development workflow, you can increase your innovative ideas while also increasing productivity.

Key features of using SpaceClaim for design include:

- Full part and assembly modeling

- Detailed drawings including full 2D/3D GD&T

- Photorealistic rendering capabilities with Keyshot

- Open/edit files from neutral and native CAD systems

- Complete help guide and tutorials for a rapid start

SpaceClaim’s intuitive interface allows users to create, edit, and prepare models for 3D printing faster and more efficiently than before. With the STL prep module (faceted data toolkit), you can work directly with STL files as well as leverage automated many prep tools for 3D printing applications.

Intuitive workflows inquire of a faceted file’s integrity and further repair the file to a printable model. Regardless of the imperfection, such as overlapping, intersecting, or over-connected triangles, SpaceClaim’s tools will rapidly and automatically heal all STL bodies so they are print ready.

Next, solid-like operations help you ensure your faceted data is just the way you want it. Use familiar manipulation tools like Pull and Move to edit a collection of facets and change the form of the model. Boolean tools let you add or subtract surface or solid data from the faceted model, giving you further freedom to rapidly make changes.

Optimization tool mean you can smooth facets and reduce noise from a course scan of an object. Shelling and infilling help balance the strength the weight ratio, while minimizing material consumption. And finally, a series of analysis tools helps ensure your model has adequate wall thickness and overhang protection in critical areas.

The hybrid nature of SpaceClaim’s STL prep module means you can combine the best of solid modeling techniques and the flexibility of its STL editing tools. You can choose which tools will get you to the optimized result you desire.

Multi-Purpose 3D modeling for faster engineering results

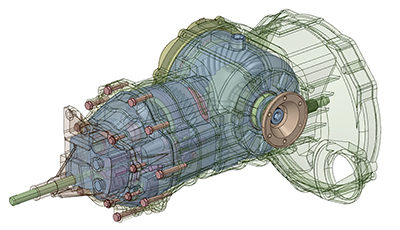

ANSYS SpaceClaim™ is a multipurpose 3-D modeling application providing efficient solutions to common modeling tasks. Built on the direct modeling technology, SpaceClaim removes geometry problems associated with various 3-D CAD operations, such as design or concept modeling, repair of translated CAD files, general model de-featuring, and complete model editing. With its premise of ease of use and simplicity, you’ll find SpaceClaim to be extremely valuable in tackling small to large modeling problems.

A new way of 3-D Modeling

The unique user interface, modeling technology and versatile toolset enable you to easily create and modify geometry without the complexity associated with traditional CAD systems. When working with existing CAD models, you can de-feature and simplify geometry with automated, easy-to-learn tools. SpaceClaim is ideal for engineers who don’t have time for heavy CAD tools but want and need to get fast answers using 3-D.

Ease of Use

We believe that technology should work for you, not the other way around. Technology should make your job easier, not more complicated. SpaceClaim enables you to create, edit, or repair geometry without worrying about the underlying technology. With SpaceClaim, working with 3-D modeling software becomes fast, easy, flexible, and rewarding, no matter where in the workflow you need it. Regardless of a model’s origin, you can open the file in SpaceClaim and add or subtract geometry in any way you visualize. With streamlined commands and workflows, operations that previously took hours can be completed in minutes. You’ll find learning SpaceClaim easy — weeks instead of months – and realize a return on your investment that’s faster than expected.