Verisurf Model-Based Inspection & Measurement Software

Verisurf software has earned a leadership position in model-based measurement technology by pioneering real-time deviation between manufactured parts and associated CAD models. As an independent software developer, Verisurf Software supports open CAD standards and integrates with all brands and models of measurement devices for CMM Programming with their Universal CMM platform.

Jump to Verisurf products:

Software Solution Suites

To meet your specific needs and budget, Verisurf offers different Software Suites. At MCAM Northwest, we can help you decide which suite is the best fit for your business’ needs. Contact our Sales team today to get a quote!

Teach programs or create them from CAD for measurable reduction in programming time and process execution. Run CMMs with Renishaw, Mitutoyo, Hexagon, Zeiss, or Pantec controllers, create reports and connect to quality databases.

The marriage of CAD and metrology, reliably connected to tool-building is a worldwide standard set by Verisurf. Interactive graphical experience, the user interface provides clever graphical interaction and live feedback that makes the user experience 100% intuitive.

Probe and scan directly with scanners and CMMs that include API, Creaform, FARO, Hexagon, Kreon, Leica, Mitutoyo, Renishaw, WENZEL, and Zeiss. Extensive point cloud and mesh editing tools to automate 3D modeling including feature recognition and auto surfacing. Create NURBS surfaces and Parasolid solid models with model associative GD&T and export to popular CAD formats.

Connect to manual and portable CMMs and measure with probes and scanners that include API, Creaform, FARO, Hexagon, Kreon, Leica, Nikon, and more. Inspect to drawings or CAD models with intelligent MBD and measure primitive features or complex profiles directly without limitation. Create meaningful quality reports in standard or custom formats and connect to popular first article or SPC quality management databases.

Want to learn more about Verisurf Software? Click here to read the Product Spotlight blog!

Want to learn more about Verisurf Software? Click here to read the Product Spotlight blog!

Verisurf CAD

Verisurf CAD is the foundation of all Verisurf suites and makes our software unique in the metrology industry. Verisurf software is different because it not only imports every major CAD file format; it is a complete 3D modeling application.

Verisurf is the only metrology software that includes wireframe modeling, NURBS surfacing, Parasolid solid modeling, 2D drafting, and Model-Based Definition (MBD) that automates manufacturing.

Key Features

- Import large, complex CAD models with intelligent GD&T for fast model-based inspection planning and quality reporting

- Select measured features, modify values for design intent as required, then one-click export to CAD for automated 3D design and modeling

- Metrology productivity TOOLS to quickly define coordinate systems, correct surface normals, find holes, and create 3D PDF files

Verisurf Measure

Measure part features and complex profile geometries informed by real-time deviation display between CAD and measured data for real-time decisions. Produce one-click inspection reports in standard or custom, shareable formats that feed to your quality management system.

The Measure module’s device interface operates and optimizes most popular measurement systems making them more productive and ensuring a better return on your investment. You can also import externally captured data and process it against the nominal CAD model and tolerances. Even run datasets offline with feature extraction and pre-defined datums and constraints.

Key Features

- Easily automated inspection plans for repeatable device alignment, measurement, and reporting using semantic, associative model-based definition

- Connect to multiple devices simultaneously and quickly switch between individual point probing, tactile scanning, and 3D non-contact scanning

- GD&T (Geometric Dimensioning & Tolerancing) measurement simplified – apply callouts, associate feature relationships, and employ datum reference frame controls with only basic training

Verisurf Build

Verisurf BUILD is the industry-leading tool for real-time model-based inspection, tool fabrication, and computer-aided assembly.

Inspect position and profile, set details and fabricate tools, jigs, and fixtures faster and at lower cost than any other process or software.

Evolved and perfected from a large installed base at today’s modern aerospace, automotive, and industrial tooling manufacturers.

Key Features

- Quickly begin the important part of your inspect or build project with Verisurf’s fast, accurate alignment of CMM to CAD model

- Real-time deviation display, enhanced by live interaction between the onscreen probe and CAD, responding to probe proximity, and streaming immediate positional detail

- Numerous deviation gages, color indicators, and digital readouts, interact with intelligent GD&T from the model, which also sets tolerances for inspection reporting

Verisurf Analysis

Simplifies part inspection through the comparison of measured points, clouds, and meshes, to all CAD file formats. Check part characteristics such as position and profile quickly and easily using a variety of alignment, analysis, and reporting techniques.

Analyze to CAD with imported data sets or directly from measured points, clouds, or meshes from 3D measuring devices including portable probing and scanning systems and both manual and CNC CMMs to analyze part tolerance compliance.

Key Features

- Automatically apply model-based tolerances from CAD product manufacturing information

- Fast analysis of data to all CAD formats and entity types, with powerful and easy-to-use best-fit features offering extensive constraint options

- Instantly identify quality issues with vibrant color deviation maps and create inspection reports in all common output formats

ANALYSIS is at the heart of the Inspection & Analysis Suite, which includes these modules:

- CAD – Verisurf’s foundation module that includes a comprehensive computer-aided design system.

- MEASURE – Interface to the CMM’s control system, joystick measuring, reporting, Teach Mode, and more.

- ANALYSIS – Analyze measured data to any CAD Model and create revealing inspection reports.

Verisurf Reverse

Verisurf’s 3D scanning and reverse engineering software Verisurf Reverse can generate 3D CAD models from point clouds captured from non-contact measurement methods, such as laser scanners, photogrammetry and arms (like the 3DGage).

Included in Verisurf’s 3D Scanning and Reverse Engineering Suite, Reverse creates, manages and reverse engineers point clouds that can be made into meshes and surfaces for manufacturing, inspection and tool fabrication.

By utilizing its advanced metrology tools, Verisurf Reverse creates and custom-fits lines, arcs, planes, splines, spheres, freeform surfaces, and more, even with sparse data.

Save RE Models in Numerous CAD Formats

- IGES

- STEP AP242

- STL

- CATIA V4/V5

- AutoCAD

- ACIS (SAT )

- Parasolid

- CADKEY

- VDA

- ACSII

Highly-Accurate Automated Surfacing

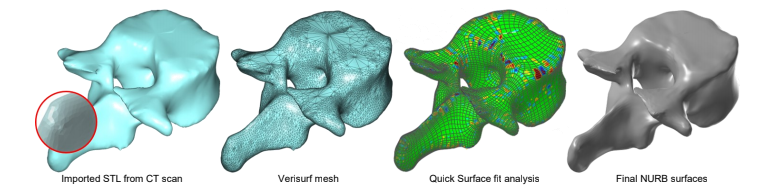

The Quick Surface option allows for creating more simple, more accurate modeling from meshes, derived from scan data or STL files. Quick Surface generates complex polygonal meshes with very little button-pushing, making it easy for novice users to navigate.

To learn more about Quick Surface, watch the video demonstration:

Features

- Load data from any scanner using industry-standard

STL, colored PLY, or OBJ mesh files - Reduce and clean up the number of polygons while

keeping the original reference mesh for best results - Quad surfacing enables freeform surface reconstruction

(not possible with standard surfacing methods) - Real-time fit analysis and advanced snap-to-mesh

Technology allows novices to create shapes in no time - Easily create smooth, high-quality NURB surfaces on

organic shapes with the click of a mouse button

Want to learn more about Verisurf Reverse? Click here to read this Product Spotlight blog!

Want to learn more about Verisurf Reverse? Click here to read this Product Spotlight blog!

Master3DGage® PCMM for 3D Inspection

Powered by Verisurf’s industry-leading inspection software, this handy, quick-mount CMM system allows easy setup for on-demand measurement and inspections anywhere on the shop floor. Use Master3DGage® right on your machine to verify parts quickly, in process, without removing or re-positioning them.

Finish typical inspections, such as blueprint, in-process, incoming, first article and final inspections, quickly—with surprising ease and accuracy. Measurement reports are generated automatically, in industry standard formats, so you can know immediately whether parts are in or out of tolerance.

Productivity-minded machine shops seeking an affordable, best-in-class CMM will find everything they need in Master3DGage®.

NO METROLOGY EXPERIENCE NEEDED

With Master3DGage®, simplicity and ease of use are designed right in. Even those with little or no metrology experience can get up to speed quickly. The controls and interface are easy and straightforward, so users spend less time scrolling through screens and more time making quality parts.

ALIGN, INSPECT, REPORT—SIMPLE, REPEATABLE THREE-STEP PROCESS

ALIGN

Quickly automate alignment by picking targets on CAD features (datums).

Run the routine by probing each target on the part. The Master3DGage® software walks you through the process with simple, step-by-step instructions.

INSPECT

Inspect and view in real time by manually probing or by following automated inspection plans. Easily measure features from precise single points to point clouds. Powerful software technology displays variance between the 3D model and the part.

REPORT

Using the 3D CAD model as the nominal definition, the system quickly generates custom reports in industry standard formats, including GD&T constraints and color deviation maps, for clear, practical analysis.

Ultra–accurate, six-axis metrology for precise 3D inspections

Master3DGage® features an integrated Hexagon Metrology, six-axis CMM—among the world’s most accurate—offering a remarkable measuring volume of just 1.2m. This feature provides superior dimensional control of parts, tooling, molds, castings and more.

Powered by Verisurf’s world-class, model-based software, Master3DGage® maintains precise digital workflow, from the start of your inspection to the end. The ability to precisely pinpoint and resolve quality issues in real time helps reduce scrap, improve efficiency and boost the productivity of every machine.

What’s the bottom line? With the new Master3DGage® you’ll do more work, with less rework—because both process and results are repeatable, even during high-volume production.

Verisurf Automate

Verisurf AUTOMATE programs and operates CMM’s faster, easier and at a lower cost with a 3D CAD measurement platform that automates all types and brands of coordinate measuring machines. An intuitive 3D experience combined with visual object-oriented programming and open standards all contribute to reducing training, support, and maintenance costs while increasing freedom of choice.

Features

- Easy online programming in “Teach Mode” or fast offline programming with standard CAD formats; ACIS, AutoCAD, IGES, Inventor, KeyCreator, Mastercam, Parasolid, Rhino, Solid Edge, SolidWorks, SpaceClaim, STEP, STL, and VDA or optional CAD formats; CATIA with FTA, Siemens NX, and PTC Pro/ENGINEER Creo.

- Visual object-oriented sequencing and CMM probe path generation quickly create automated inspection plans, executes them, and generates reports.

- Intelligent tree objects with drag and drop re-ordering are easily edited with logical right-click options.

- Probe points and paths are created and edited dynamically on CAD features or surfaces including specialized routines for helical and radial surfaces.

- Verisurf’s open 3D measurement platform strategy means inspection plans can be executed on any supported stationary or portable CMM increasing flexibility, eliminating inspection bottlenecks, and reducing training and support costs.

Universal CMM

You no longer need to tolerate proprietary or outdated CMM software that came with your CMM. With Universal CMM you can run your Verisurf programs on most models of motorized CMMs from the world’s leading manufacturers. This means you don’t have to maintain different software for each proprietary CMM or endure reduced productivity because the one person who knows how to use the proprietary software is unavailable.

Features

- Plug and play CMM communication for Hexagon Dea, Leitz, Mitutoyo, Wenzel, Pantec, Nikon, LK or Zeiss™️ machine controllers, as well as Renishaw, Tesa, Hexagon Leitz or Zeiss™️ head controllers.

- Optional support for scanning probes and error mapping compensation for geometric, volumetric, orientation, positioning and kinematic errors in the CMM structure that affects accuracy.