Blade Expert

Blade Expert

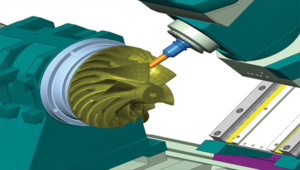

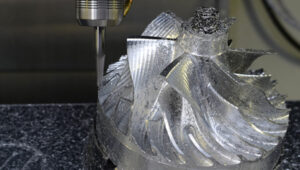

Generating toolpaths for impellers, fans, and marine propellers is a complex 5-axis challenge. Machining these multibladed shapes usually requires special multistep, multiaxis programming, but Mastercam Blade Expert provides a comprehensive solution for various blade configurations. The interface follows the Mastercam standard used by all Multiaxis toolpaths, ensuring a short learning curve and successful deployment. Blade Expert turns your multiblade machining challenges into routine solutions:

- Remove the material from between the blades.

- Finish the blades/splitters.

- Finish the floor.

- Finish the fillets.

Applications

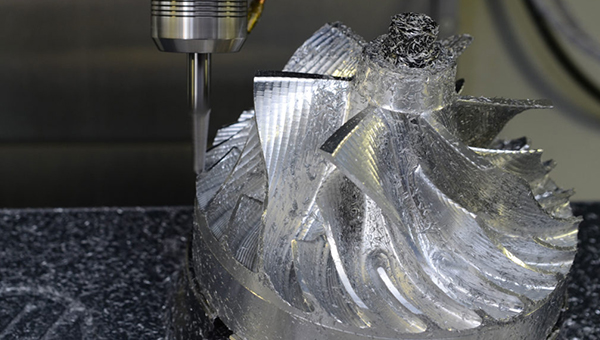

The most common application is to machine multibladed rotating parts for air or gas handling equipment. Blade Expert precisely and efficiently removes material between blades and finishes surfaces with gouge-free results. It is particularly useful for manufacturing compressor wheels, impellers, propellers, turbine blades, and blisks.

Aerospace Components

Automotive Components

Energy & Power Generation Manufacturers

General Industry Manufacturers & Suppliers

Educational Institutions

Features

Efficiency

Streamline the toolpath creation process for multibladed part including fans, propellers, impellers, turbines, and marine screws. Simply define the blade and hub sections and let Mastercam generate your toolpaths. There is no limit to the number of blades, splitters, or sub-splitters that can be programmed.

Precision

Stock model awareness eliminates air cuts, and tool axis and tool tip control ensures collision-free toolpaths.

Powerful CAM

This software delivers a full array of cutting strategies and so much more. Mastercam can be customized to what your shop needs today and easily scaled to meet your future manufacturing needs.