Lathe

Lathe

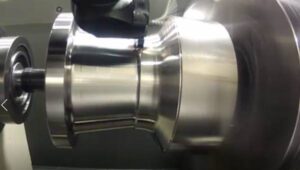

Mastercam’s lathe CAM programming software gives you a set of tools to turn your parts exactly as you need them. Mastercam Lathe provides easy roughing, grooving, threading, parting, boring, drilling, and finishing routines for increased productivity.

Mastercam Lathe also delivers a set of C-axis programming tools, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling and cross contour and drilling.

- Integrated CAD for CAM provides a powerful set of tools for creating and manipulating wireframe, surfaces, STL, and solids data including MBD information (with select translators).

- Advanced toolpath strategies turn parts with greater efficiency and precision.

More people use Mastercam than any other CAM software.

From CAD inception to the creation of a final machined part, Mastercam is designed as a comprehensive solution for manufacturing efficiency.

- Full 3D CAD modeling.

- Context-sensitive help available from all dialog boxes.

- Powerful Multiaxis tool motion.

- Mill-Turn for Lathe.

- Quick toolpath functions let you program basic parts with just a few clicks.

- Easy roughing, finishing, threading, grooving, boring, drilling, and cut off.

- Intelligent, stock-aware toolpaths.

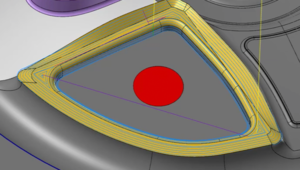

- Robust 3D solids and surface machining.

- Complete tool library and custom tool support.

Features

Efficiency

Quickly translate geometry and create a part transfer operation from the main spindle to sub spindle and/or a bar pull operation prior to a cutoff toolpath.

Intelligent ID and OD Roughing

Includes roughing to a boundary for castings.

Live Tooling

Machine any job with the combined power of C- and Y-axis machining.

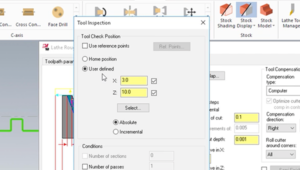

Tool Inspection

Automatically stop machining to check the insert during your roughing, finishing, and grooving operations.

3D Tooling Support

Available in Mastercam Lathe, Mill, and Mill-Turn.

Accelerated Finishing

Take advantage of innovative profile tools and processes aimed at greater efficiency and higher machining productivity.

Click here to view 5 crucial updates to Mastercam Lathe that will ramp up your productivity in this Product Spotlight blog!

Click here to view 5 crucial updates to Mastercam Lathe that will ramp up your productivity in this Product Spotlight blog!