Productivity +

Productivity +

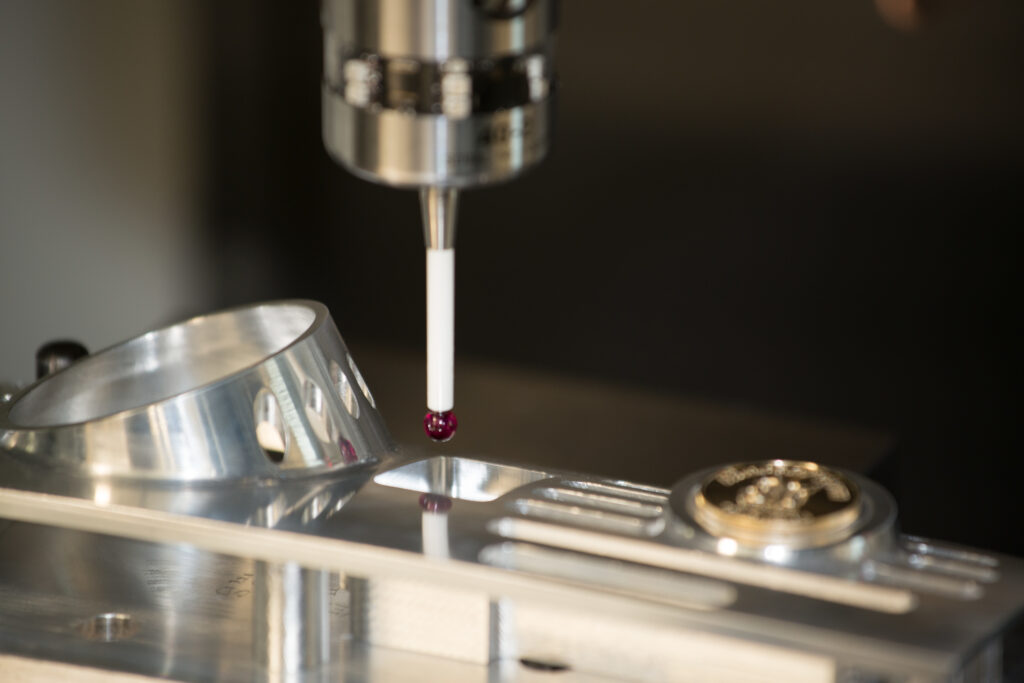

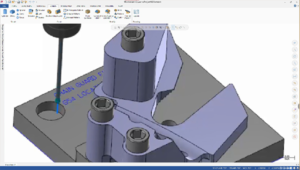

Productivity+TM is an add-on that gives you the ability to use a Renishaw measuring probe on a machine tool to update fixture offsets, tooling offsets, program orientation, and report on critical dimensions and tolerances. It also assists in lights-out manufacturing and running a machine tool without an operator.

Productivity+ provides an easy-to-use platform for incorporating simple measurement functionality and more advanced in-process intelligence into machining programs. It can simplify a wide range of measurement and process control tasks, such as component set-up, verification of critical features, and process development.

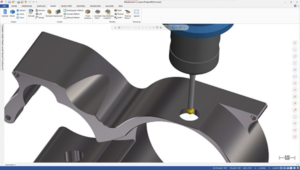

- Program and simulate a Renishaw probe for your machine tool.

- Improve process control and reporting of your machine tool’s performance.

- Available with Mastercam Mill and Mastercam for SOLIDWORKS® products.

- Perform simple measurements and alignments to set up and validate your parts at the machine tool.

Applications

Productivity+ is a Mastercam Add-On that allows you to program and simulate a Renishaw probe for your machine tools. It integrates process control into your CNC programs. Productivity+ will perform measurements and report results, allowing you to set up and validate your parts at the machine tool for better process control and performance reporting.

Aerospace Components

Automotive Components

Medical Manufacturers

General Industry Manufacturers & Suppliers

Educational Institutions

Features

Process Control

3-, 4- and 5-axis configurations are supported by a wide range of post processors to integrate process control into your CNC programs with a consistent level of functionality between machine types; transfer one probing program between machine tools by simply reposting the program.

Predictive Process Setting

Perform simple tests to ensure that a machining process will be successful. As a Productivity+ program runs entirely on the machine tool, the program forms a self-contained package which operates in exactly the same form, every time a part is run.

Smart Machining

Gain information about the in-process state of a component and the decisions involved in production. Use the probe to measure features and update machining process based on the acquired data.

Want to learn more abut Productivity+? Click here to read the Product Spotlight blog!

Want to learn more abut Productivity+? Click here to read the Product Spotlight blog!