- January 29, 2019

- Posted by: MCAM Northwest

- Category: Mastercam

What is the motivation for most people to be involved in Manufacturing? Is it outside influences such as family members, friends or even a good high school teacher that sends that individual on a pathway that squarely lands them in manufacturing? Or is it an inherent trait that had to do with the need to build things? We think those that stay long term really love manufacturing and are builders with an innate need to construct something then admire it, check it’s accuracy and show it off to their peers, customers, bosses, family, friends, etc. The best builders are always looking for the best tools to make the manufacturing process easier or faster. How is technology enhancing these tools?

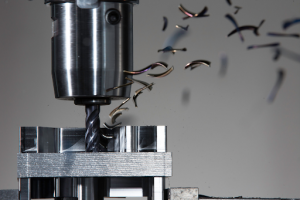

Subtractive processes have historically been how we get things done. We start with a chunk of material (stone, wood, metal, plastic, cloth, glass, etc). and cut away at it, chopping, grinding, shaping or polishing until it transforms into what we want. It is that action that defines us as builders. Today, the efficiency gains in subtractive processes are huge and broad. New software technologies for CNC programming, better CNC machines and better cutting tools. However, the waste of subtractive (process/manufacturing) can be substantial. The material that is cut away can in some cases be made into additional parts, or recycled, but not always. Then there are the machining chips, used coolant, worn out cutting tools, etc. Wouldn’t it be better if we could start from nothing and build up what we want without any waste? That transformation is well under way, and exists now.

Subtractive processes have historically been how we get things done. We start with a chunk of material (stone, wood, metal, plastic, cloth, glass, etc). and cut away at it, chopping, grinding, shaping or polishing until it transforms into what we want. It is that action that defines us as builders. Today, the efficiency gains in subtractive processes are huge and broad. New software technologies for CNC programming, better CNC machines and better cutting tools. However, the waste of subtractive (process/manufacturing) can be substantial. The material that is cut away can in some cases be made into additional parts, or recycled, but not always. Then there are the machining chips, used coolant, worn out cutting tools, etc. Wouldn’t it be better if we could start from nothing and build up what we want without any waste? That transformation is well under way, and exists now.

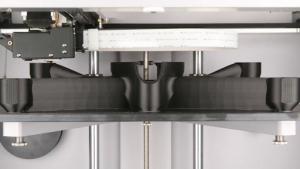

Additive processes began when we started grinding up stone and making cement to build things, heating metals and pounding them into shape or melting and pouring them into wet sand shaped  to what we want, that was the start of some of the fundamental concepts of how our modern additive processes work. Now we take a material, usually heat it, dispense it through nozzle, point it in the right direction and let shapes materialize before our eyes. We start with nothing, pour or dispense the material into some sort of form or mold or we let a computer position and guide the nozzle, as the material hardens behind the motion.

to what we want, that was the start of some of the fundamental concepts of how our modern additive processes work. Now we take a material, usually heat it, dispense it through nozzle, point it in the right direction and let shapes materialize before our eyes. We start with nothing, pour or dispense the material into some sort of form or mold or we let a computer position and guide the nozzle, as the material hardens behind the motion.

Our needs as builders are more fulfilled virtually now. We shape parts in both an additive or subtractive process known as boolean operations in a solid modeler. We create the virtual part, then decide if it will be produced using subtractive, additive or a hybrid of the two process types. As we move towards industry 4.0, one of the biggest changes relates to subtractive processes being supplemented by additive processes. More and more manufactured components are being re-engineered to be produced more efficiently with additive rather than the traditional subtractive processes. I see this as a marriage or hybridization between the two process types. Either way, myself, along with the builder personalities who really love manufacturing, will be happy with the results and can gain the same level of satisfaction while utilizing the combination of subtractive and additive processes for our rapidly changing world.