- October 22, 2024

- Posted by: MCAM Northwest

- Categories: Mastercam, Tech Tip

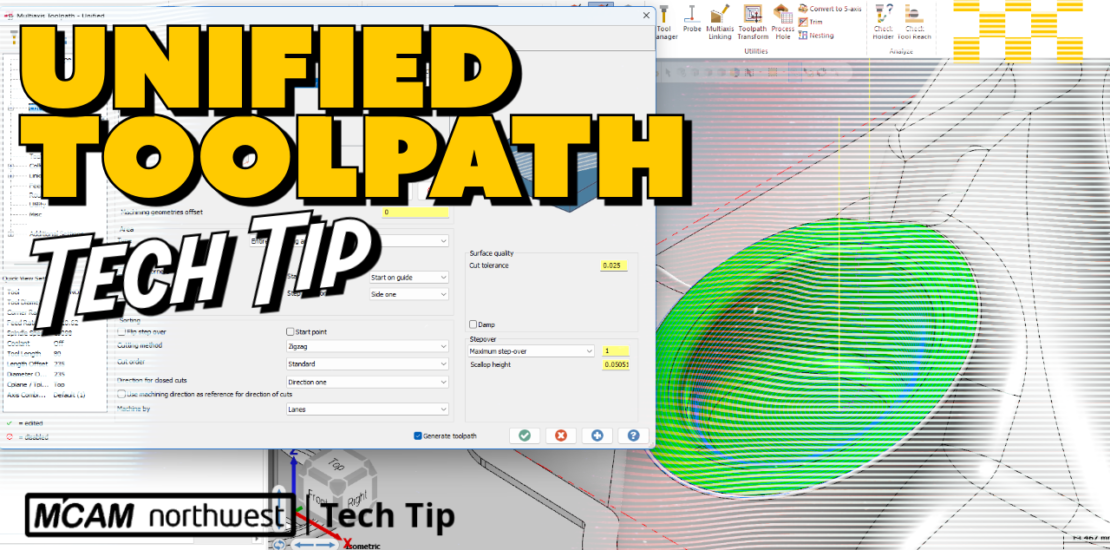

Mastercam Tech Tip: Mastering Multiaxis with the Unified Toolpath

Ready to unlock the full potential of your multiaxis machining? The Unified Toolpath in Mastercam is your secret weapon for faster programming, flawless precision, and ultimate flexibility. Unified allows you to switch between various cut patterns quickly and easily, without the need for multiple toolpaths.

Whether you’re tackling complex 3D surfaces or standard 3-axis operations, Unified has you covered. In this post, we’ll explore the key features of the Unified Toolpath and show you why it’s a must-have for any CNC programmer looking to optimize their multiaxis machining.

What is the Unified Toolpath in Mastercam and how does it improve multiaxis machining?

The Unified Toolpath in Mastercam simplifies multiaxis machining by combining multiple toolpaths, like morph and parallel, into one. It allows users to easily switch between cutting patterns without reprogramming, saving time and improving precision. Ideal for 3-axis to 5-axis machining, Unified enhances flexibility, control, and efficiency in handling complex surfaces and geometry.

How to Use the Unified Toolpath

Let’s walk through how to set it up. Here’s a quick breakdown:

1. Select Your Geometry: You start by selecting the machining geometry, such as a section of the part you want to cut. Unified allows you to easily define and adjust the areas you want to machine. Whether it’s a simple face or complex 3D surface, Unified can handle it.

2. Cut Pattern Options: The beauty of Unified lies in its flexibility. You can choose from a range of cut patterns:

- Automatic: The automatic cut type allows for several cut patterns that are based off of the perimeter of the faces selected for machining, or can be based from the center of the area of those faces. This allows for simple cut motion that gets to all faces, perfect for situations where mill finish is less important than getting the job done quickly

- Curve: create cuts that are parallel, perpendicular, guided by, morphed between, or projected from any curve. Curves can come from solid edges, wireframe entities, or a combination

- Surface: Cuts that are guided by surfaces in the model or even by other surface shapes that you can create for total control. Can also follow UV curves in surfaces or solid faces for flowline style cuts

- Plane: create planar cuts in a parallel style that align to any planar orientation you can imagine. Use named planes, standard planes, surface normals, or custom angles

3. Axis Control: Don’t need full multiaxis motion? No problem! The Unified Toolpath allows you to lock down to 3-axis or 4-axis machining when necessary. Just adjust the output format under Tool Access Control, and you’re good to go. This ensures cleaner cuts and more control over your toolpath, without the need for complex 5-axis motion where it’s not required.

Why Unified is a Must-Have

The Unified Toolpath stands out for its versatility and efficiency. Whether you’re dealing with 3-axis, 3+2, 4-axis, or full 5-axis machining, it allows you to tailor the toolpath to your specific needs with just a few tweaks. You can create everything from simple parallel cuts to complex morphing patterns with minimal effort, saving you time and boosting productivity.

This toolpath brings together the power of older, more specialized toolpaths like morph and parallel into a single, unified solution. No more second-guessing which toolpath to use—Unified has you covered!

Want to Learn More?

Unified is just one of the many powerful tools Mastercam has to offer. If you’re interested in learning more about Mastercam or multiaxis machining, feel free to reach out to us at MCAM Northwest. We’re here to help you master the latest features and techniques in CNC programming.

Give us a call at 503-653-5332 or email us at sales@mcamnw.com. And if you enjoyed this tech tip, don’t forget to like and subscribe to our channel for more updates!

Key Takeaways (TL;DR)

- Versatile Toolpath: The Unified Toolpath combines multiple toolpaths, such as morph and parallel, into one, making multiaxis machining more efficient.

- Pattern Flexibility: Easily switch between cut patterns like parallel, curve, and plane within a single toolpath, reducing reprogramming time.

- Enhanced Control: Unified allows you to limit axis movement for cleaner 3-axis machining or utilize full 5-axis capabilities when needed.

- Time and Productivity Boost: By streamlining programming and improving precision, the Unified Toolpath saves time and increases overall productivity in CNC operations.

Follow MCAM Northwest!

LinkedIn: mcam-northwest

YouTube: The MCAM Northwest

Facebook: @MCAMNorthwest

Instagram: @mcamnorthwest

X (formerly Twitter): @MCAM_NW

Come see us in person! Visit our Events page to see where we are headed next.