- September 1, 2023

- Posted by: MCAM Northwest

- Categories: Insights, Mastercam

A lot can change in 7 years! We put together a list of the most groundbreaking features added in Mastercam 2017 through 2024.

By Callie Morgan

Friday, September 1st, 2023, 9:30 AM PDT

Every version releases hundreds of new features and improvements that improve tool life, workflow, and overall efficiency. Instead of listing a couple hundred updates added between Mastercam 2017 and 2024, we put together a list of the enhancements from each version we feel are most monumental.

To see these features in action, sign up for our Time Travel: 2017 to 2024 hybrid webinar on September 13th streaming live from Clackamas Community College! Jump to a version.

- Mastercam 2017

- Mastercam 2018

- Mastercam 2019

- Mastercam 2020

- Mastercam 2021

- Mastercam 2022

- Mastercam 2023

- Mastercam 2024

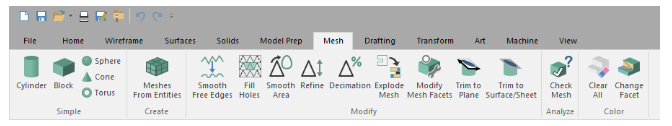

Mastercam 2017 (New UI)

This version of Mastercam was the launch of a new look for the software. The frame of small icons seen in earlier versions were replaced by the sleek ribbon-style interface organized by tabs that you see modern versions of Mastercam. In addition to a flashy new user experience, Mastercam 2017 hosted a slew of enhancements.

Instead of showing a handful of features introduced in Mastercam 2017, you can look through the What’s New PDF for Mastercam 2017.

Mastercam 2018

Mastercam 2018 hosted 128 pages of updates.

1. Guided Chaining (General)

Mastercam 2018 introduced the ability to guide and select the next entity in a chain when a branch point has been reached. Guided chaining is available in 3D Wireframe and Linked Edges mode for solids.

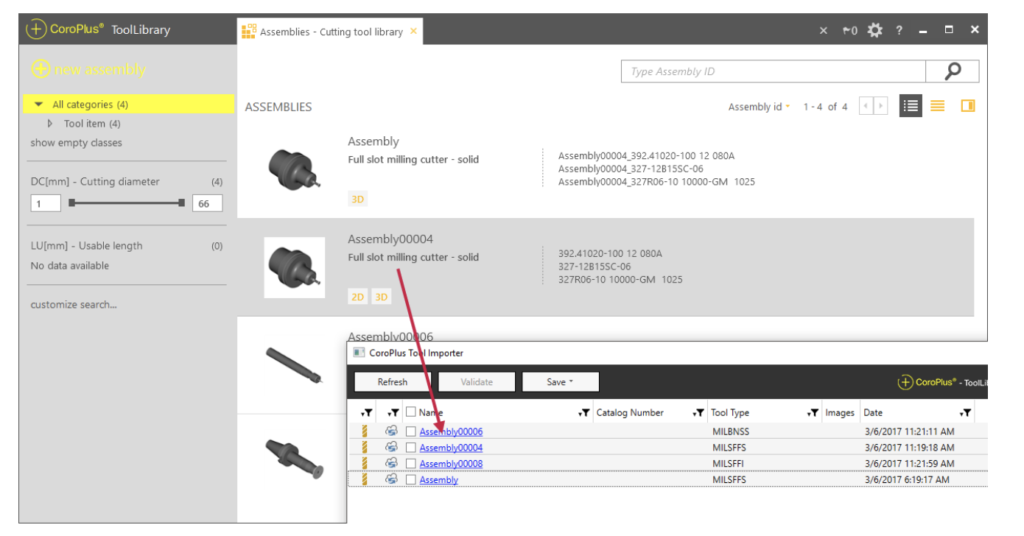

2. Tool Importers (Mill)

Support was added for importing tool assemblies from CoroPlus and Machining Cloud in Mastercam 2018.

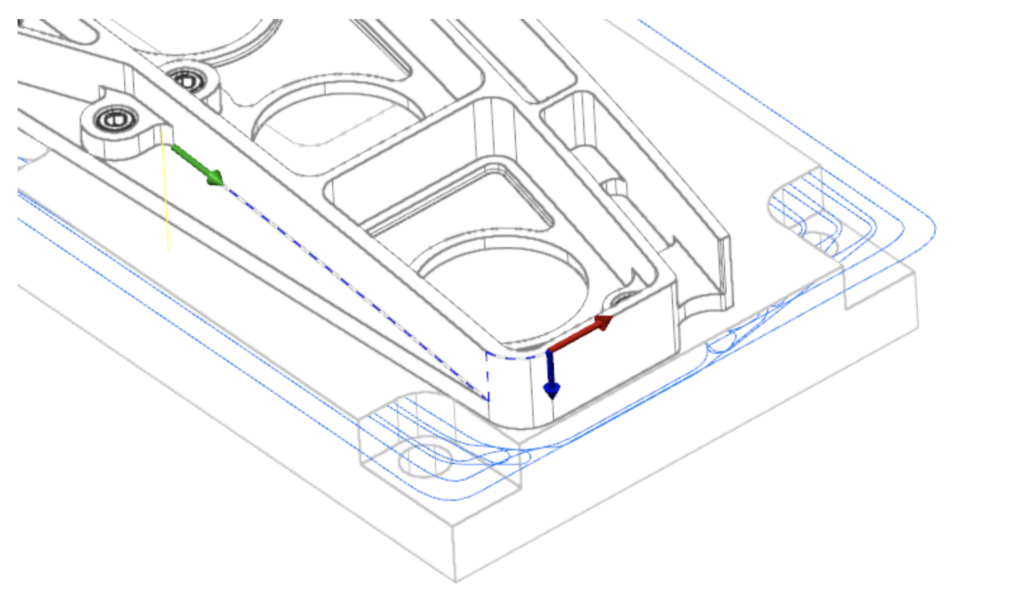

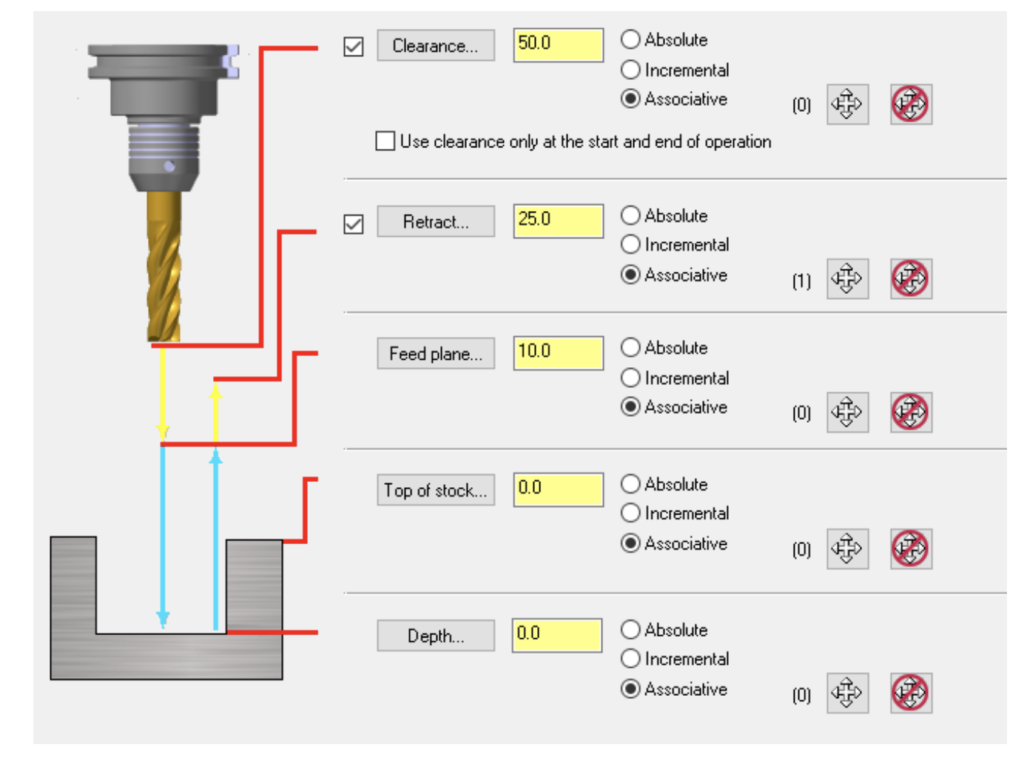

3. Linking associativity (Mill)

You can use associative points to program your linking moves for most 2D toolpaths in Mastercam 2018 on the Linking Parameters page. If the top of a feature should be cleared by a certain amount, you can enter a Clearance amount, select Associative, and then pick a point on the feature in the graphics window.

The Clearance plane will always be the specified incremental value above the point, even if the feature is moved.

4. Many additional 2D Enhancements (Mill)

There were a number of 2D features added in Mastercam 2018. The new additions include updates to Contour enhancements, Depth cut direction, Depth cut order, Finish passes, Plunge entry support, Spring passes, Stock awareness, Undercut support, and Taper support.

5. Smoothing (Mill 3D)

Smoothing controls were added to the high speed Hybrid toolpath on the Cut Parameters page. This feature is similar to the Sharp Corner smoothing options for the Finish Scallop toolpath. The Angle setting is the minimum angle between two toolpath segments that you want Mastercam to consider as a sharp angle. Blend distance is the distance Mastercam will back away from the sharp corners before and after.

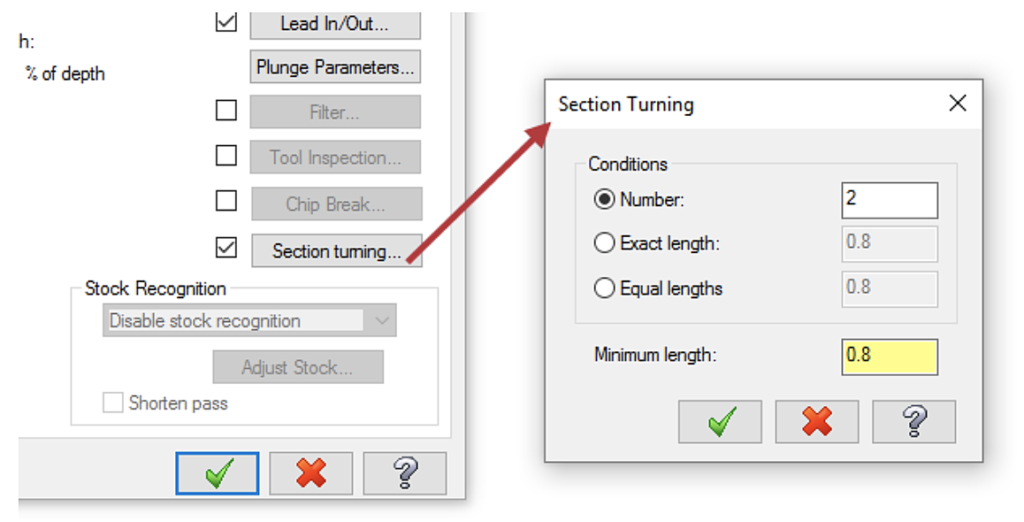

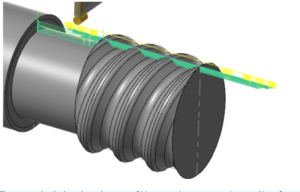

6. Section Turning (Lathe)

Lathe Rough added a Section turning option in Mastercam 2018 which lets you cut stock in multiple sections. Based on the given distance, you have a couple of options: Break the toolpath into equal sections, into sections of exact distance with one section being the remainder, or into equal sections based on the given distance.

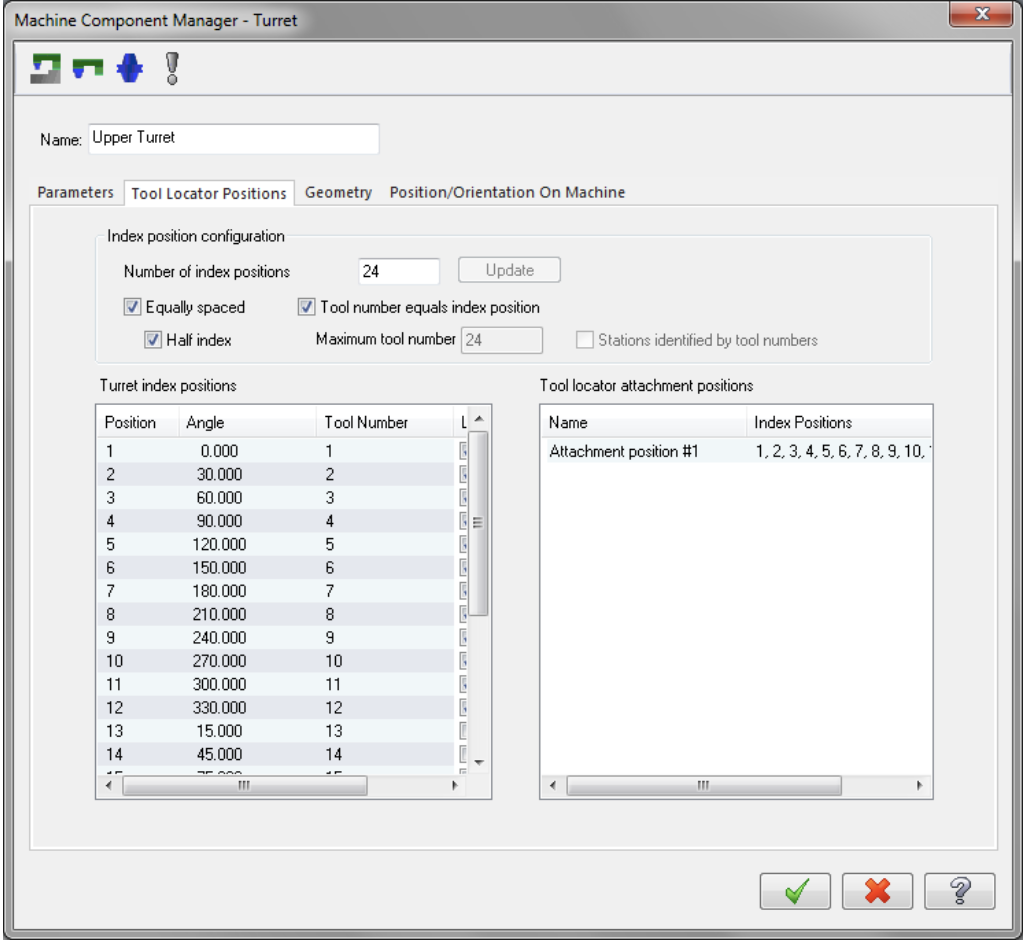

7. Multi-Station Tool Locators for Turrets (Mill-Turn )

Mill-Turn added support for multi-station tool locators for turrets, as well as half index positions, in Mastercam 2018. Tool locator positions are set in the turret setup which has been redesigned. Enter information for index positions, mounting locations, and several other options, including if half index locations exist.

Mastercam 2019

Mastercam 2019 hosted 92 pages of updates.

1. Section View (General)

The Planes Manager added in Mastercam 2019 allows you to create a section view by cutting a plane.

2. Power Surface (General)

A new function, Power Surface, was added to the Surfaces tab in the Create group in Mastercam 2019. Power Surface gives you the ability to easily create surfaces from curves, influenced by adjoining surfaces.

3. Accelerated Finishing (Mill)

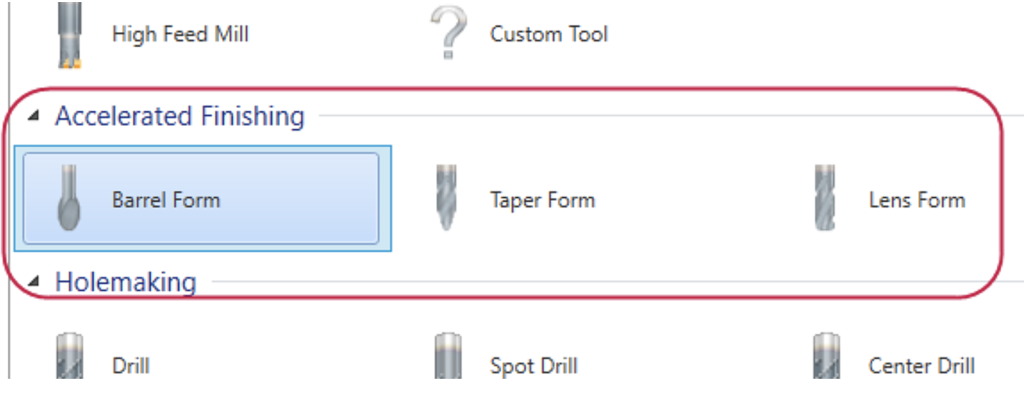

Mastercam 2019 added two new tool types, Lens Form and Taper Form to Accelerated Finishing group. Mastercam’s Accelerated Finishing technology increases material removal and finishing quality without increasing machine cycle time. Barrel Mill has been moved to the Accelerated Finishing group, and additional variations of this shape became available in later versions of Mastercam.

4. Model Chamfer Toolpath (Mill 2D)

Mastercam 2019 introduced the new 2D machining toolpath Model Chamfer. This toolpath allows you to machine safe horizontal chamfers on solid models. This toolpath only supports the following Chamfer mill tool types: Solid edges and faces for Chain geometry, and surfaces, solids, and meshes for Avoidance.

After selecting your Chain geometry, Model Chamfer has several unique parameters for increased control over the toolpath motion. For example, you can enter a Side clearance for the Solid model, which is the distance away from the solid model you want the vertical part of your flute to clear.

5. Equal Scallop Toolpath (Mill 3D)

Mastercam 2019 introduced a new 3D high speed toolpath: Equal Scallop. This toolpath creates a consistent scallop motion relative to stepover distance, producing a superior surface finish compared to 3D HST Scallop.

6. Deburr Toolpath (Multiaxis)

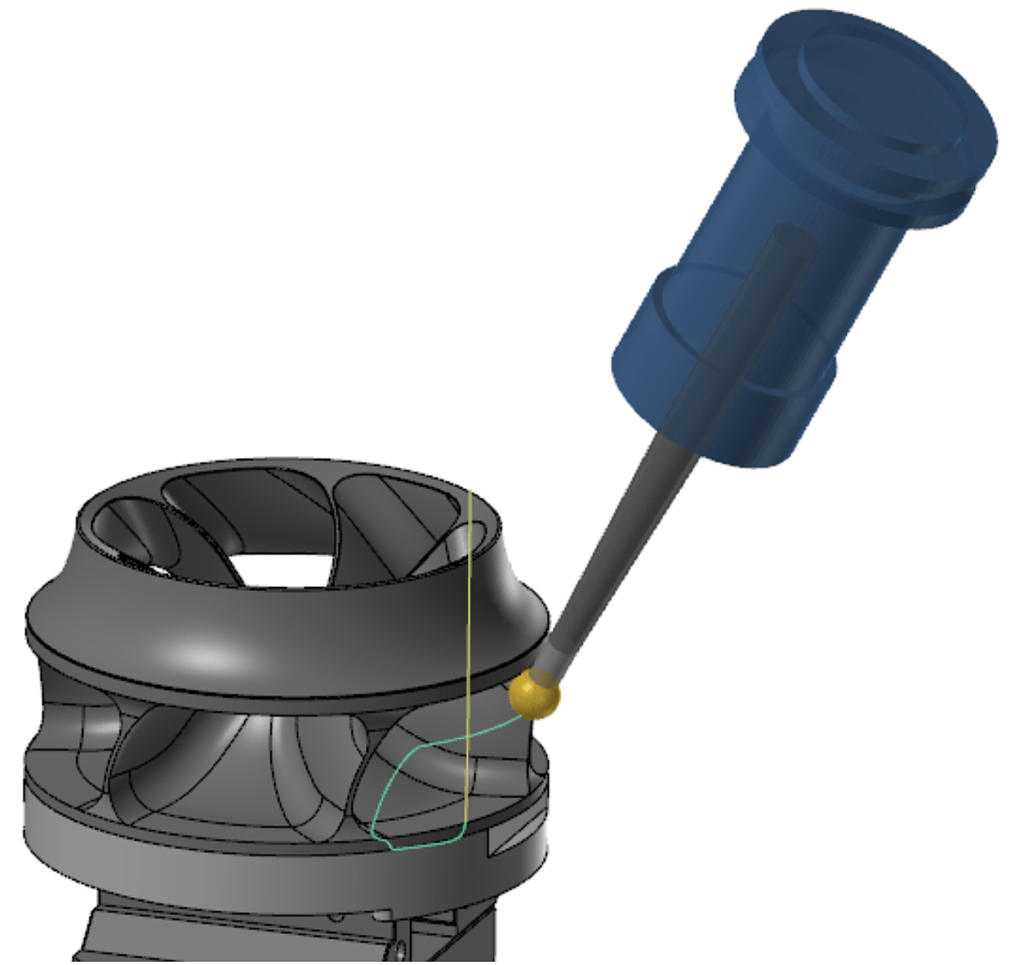

The Deburr toolpath was introduced in Mastercam 2019 to automate the removal of burs and break edges for 3-to-5 axis. In this version, the only tools supported by this toolpath were Ball end mill and Lollipop with undercut. Jump to the Mastercam 2024 section to see how this has changed.

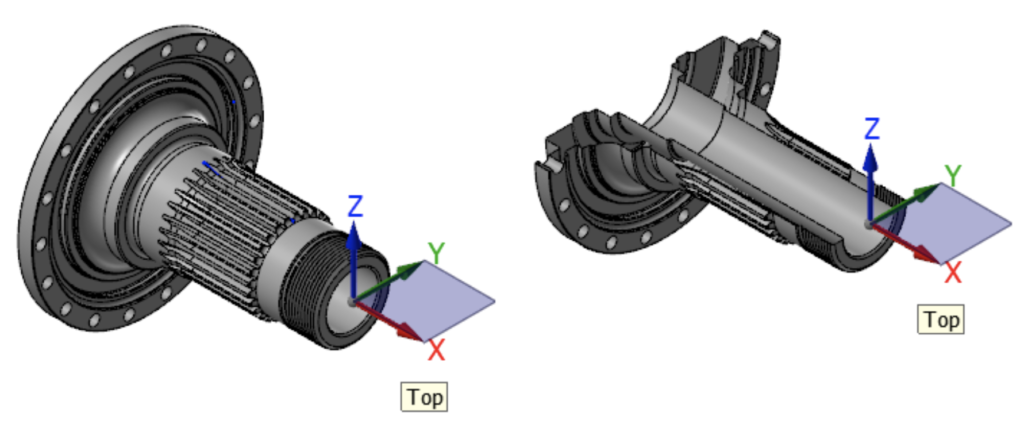

7. 3D Tool Support (Lathe)

Mastercam 2019 introduced support for building tools from 3D STEP models, with Tool Designer. To create a 3D tool, select Create 3D tool from the right-click menu in the Lathe Tool Manager dialog box.

The Tool Designer has a tab-style navigation that provides a structured workflow similar to using a wizard. You can define tools, assign them to operations, and view them when running Classic Backplot and Mastercam Simulator.

8. Mastercam Lathe for Swiss Machines (Mill-Turn)

Note: Lathe for Swiss Machines is only available in the United States.

Mastercam 2019 introduced support for Swiss machines through its similar Lathe solution. Swiss users with active Lathe and Mill/Mill 3D licenses could now take advantage of Lathe and Mill toolpaths. Mastercam provided milling, grooving, and engraving strategies for milling tools.

A wide variety of post processors became available to support Mastercam Lathe for Swiss. These post processors are created and maintained by our Mastercam partners, Postability, Inc. and In-House Solutions, Inc.

Mastercam 2020

This version contained 79 pages of updates.

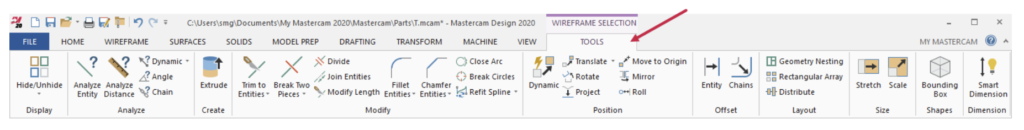

1. Contextual Ribbon Tabs (General)

To further streamline their ribbon interface, Mastercam 2020 included contextual ribbon tabs that display when you select different types of geometry in the graphics window. This sped up the process of making design changes to your parts. For example, if you select only wireframe geometry, an extra ribbon tab titled Wireframe Selection displays tools that you might need for analyzing or editing. Similar tabs display when you select solid, surface, mesh, or a mixture of geometry types.

2. Model Prep Push-Pull (General)

Mastercam 2020 added the ability to create a new solid body with Push-Pull, instead of modifying the source solid. To extend or shrink the solid body, select Move. To create a new body using the selected face as the base, select Copy.

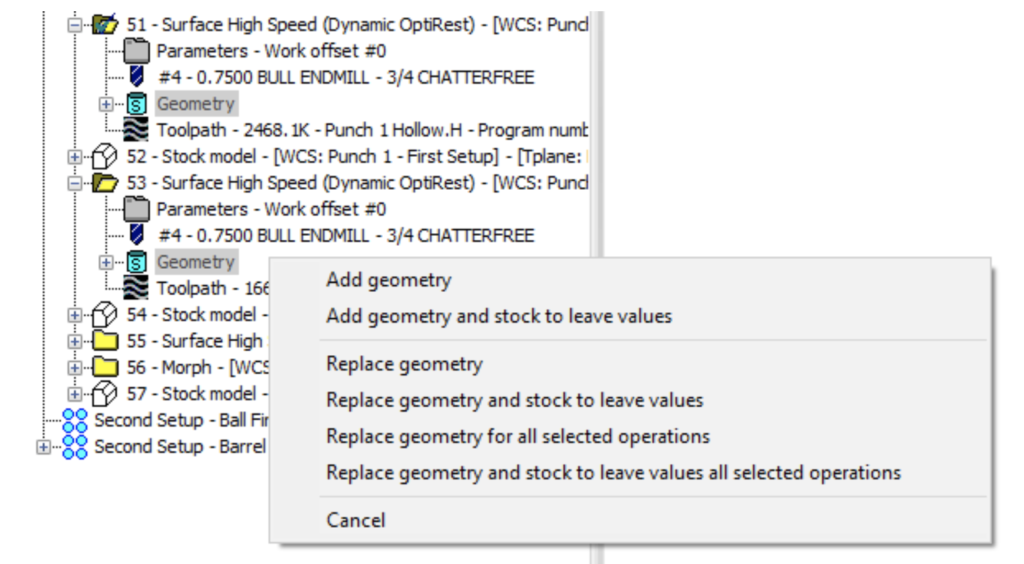

3. Dragging and Dropping Toolpath Geometry (Mill)

When dragging geometry from one 3D HST operation to another in the Toolpaths Manager, the pop-up menu in Mastercam 2020 displays more options for copied geometry.

4. New 3D Blend Toolpath (Mill 3D)

Blend, was added to the 3D High Speed suite of toolpaths in Mastercam 2020. Blend is based on the Surface Finish Blend toolpath, however, it is faster and has a superior quality. This toolpath also includes use of stock and holder checking. This also brought a blend toolpath to the Mill-Turn product.

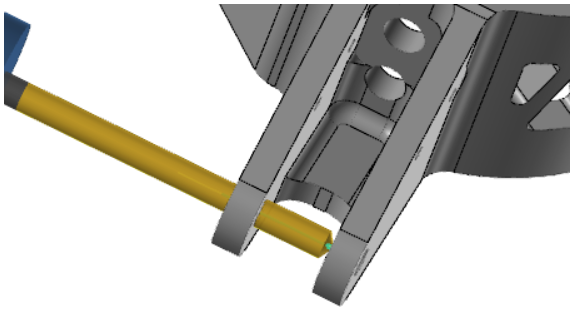

5. Hole-Making Enhancements (Multi-Axis)

Note: You must have a Multiaxis license to access this functionality.

The Multiaxis Drill and Circle Mill toolpaths were removed from Mastercam 2020. Helix Bore, Thread Mill, 2D Drill, and 2D Circle Mill toolpaths were granted multiaxis capability, accessed through the Tool Axis Control page in their toolpath dialog boxes. Additionally, if you open a file created in a previous version of Mastercam that had Entity type set to Points/Lines, the selection now retains the lines and will display them in the Toolpath Hole Definition panel.

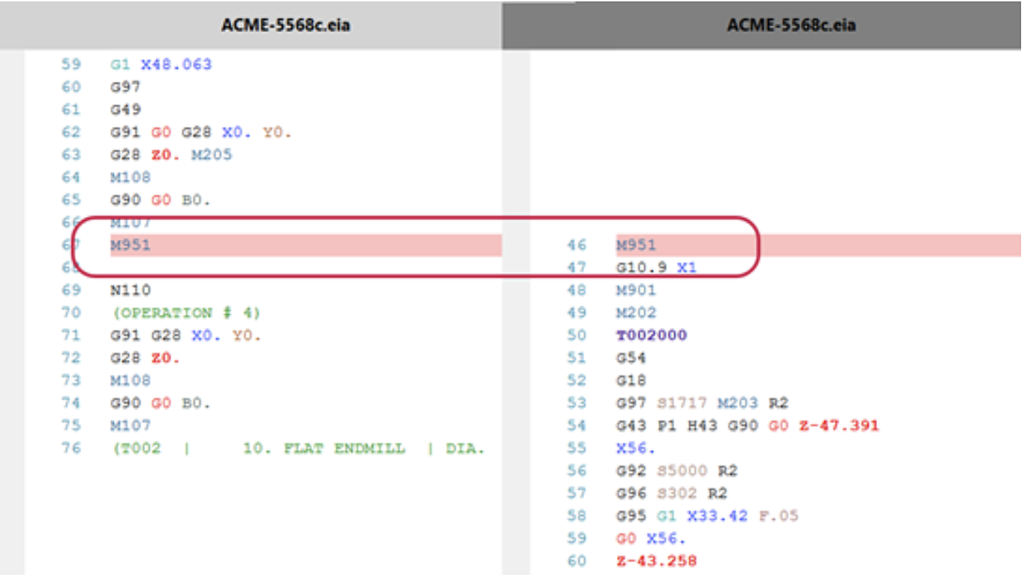

6. Improved Support for Multi-stream Output (Mill-Turn)

Code Expert added several new features for working with multi-stream NC files with Mill-Turn in Mastercam 2020. The added controls allows you to toggle between single-stream and multi-stream view without re-posting. The Align Syncs function displays multi-stream outputs with the syncs or wait codes lined up.

Mastercam 2021

Mastercam 2021 had 186 Pages of updates.

1. Note Enhancements (General)

Note is the preferred method of creating text for notes, labels, and toolpath

geometry. Mastercam 2021 made it easier to create text for notes and labels by adding the functionality of the Create Letters to the Note function. This re-designed function panel improves usability with more options and increased control.

2. Detecting and Creating Custom Holes (General)

Mastercam 2021 can recognize complex hole geometry, including intersecting and non-conventional holes, in solid bodies with no history. Once these holes are detected by Mastercam, you can use expanded options in the Hole function to save your custom holes to a template for future use. Additionally, you aren’t limited to the Mastercam default hole styles, you can create any style custom hole and save it to a library for future reuse.

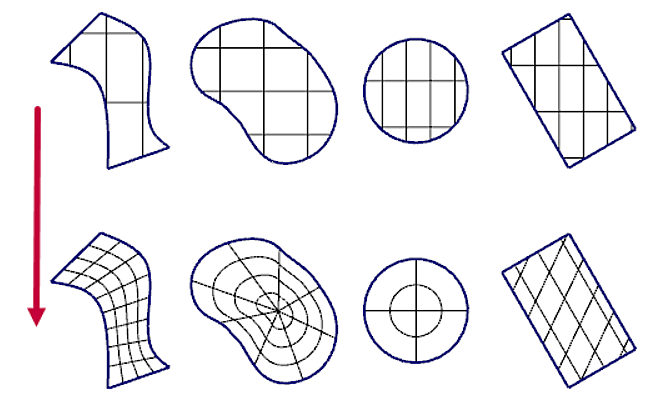

3. Redefining Surface Flow (General)

Mastercam 2021 introduced Reflow UV and Edit UV to to analyze and modify the UV direction on surface models to redefine the flow. With Reflow UV, you can redefine the flow by specifying a rotation angle or new boundary curves.

4. Checking Your Tool and Holder Against Model Geometry (General)

Check Tool Reach became available in Mastercam 2021. This feature checks your tool and holder against the selected model geometry to view where the tool can and cannot reach.

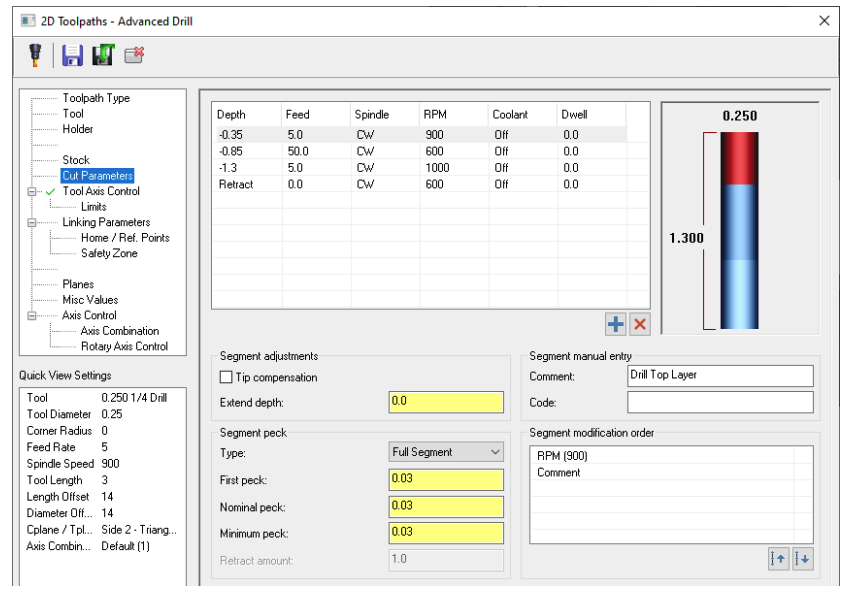

5. Machining with a Customizable Multi-Segment Drill Cycle (Mill)

Mastercam 2021 introduced the Advanced Drill toolpath. Advanced Drill is a customizable multi-segment drill cycle that is useful for spot drilling, deep hole drilling, and back spot facing. Each segment of the drill cycle can be defined in a table on the toolpath’s Cut Parameters page.

6. Pre-Machining Corners for Dynamic Mill Toolpaths (Mill)

The Corner Pretreatment page was added to the Dynamic Mill toolpath in Mastercam 2021. The options on this page can be used to set parameters on any corners in the selected machining regions before machining the rest of the part.

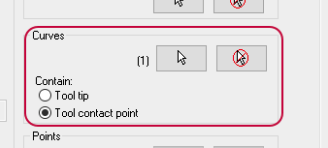

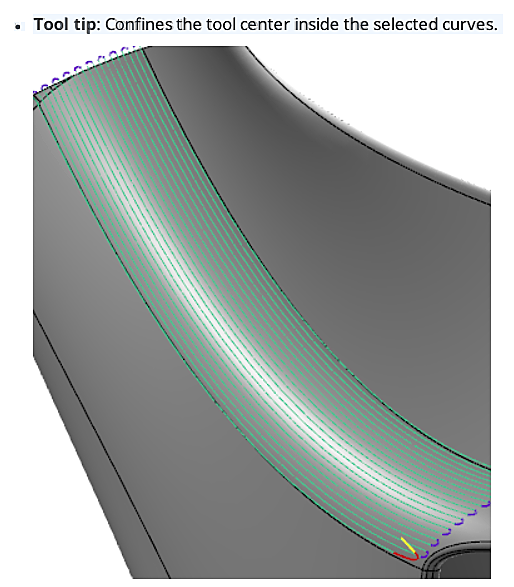

7. Confining Curves to Tool Tip or Tool Contact Point (Mill 3D)

Selected curves can be confined on the Toolpath Control page to either the Tool tip or Tool contact point in Mastercam 2021. Tool tip confines the tool center inside the selected curves.

8. Machining Custom Thread Forms (Lathe)

Mastercam 2021 introduced the Lathe Custom Thread toolpath to support custom thread forms. The panel interface simplifies and streamlines your programming workflow. You can select chained geometry to represent the thread cross-section or select either Rope, Buttress, Square,or Trapezoidal parametric definitions.

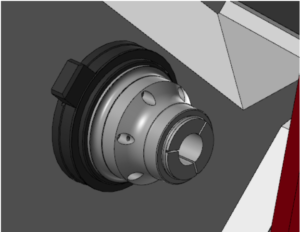

9. Support for Collets and Collet Chucks (Mill-Turn)

Mastercam 2021 Mill-Turn added support for collet chucks and collets as individual component types. This greatly expanded the range of machines directly supported by Mill-Turn.

Collets and collet chucks also became fully supported by Machine Simulation. They can be modeled either parametrically or by choosing a solid model of the component.

10. Creating 3D Tools with Multiple Inserts (Mill-Turn)

Mastercam 2021 included support for multiple inserts with 3D tools in the Tool Designer panel. Defining multiple inserts is the same process as single-insert models. Right-click in the insert list and choose New Insert from the pop-up menu. Mastercam then displays the Insert page where you define the new insert the same as previous 3D tools.

Mastercam 2022

Mastercam 2022 had 186 Pages of updates.

1. Expanded functionality of the Mastercam Learning Edition (General)

Mastercam 2022 introduced a new way to run the Learning Edition (formerly the Mastercam Demo/HLE) version of the software. The learning edition opens with the same executable file as the core Mastercam application and is available under a free software license. Additionally, Port Expert, Blade Expert, Productivity+, ProDrill, Mill-Turn .machine environments, the Zip2Go utility, Migration Wizard, export to STL and 3M are accessible in the learning edition, and can be updated using the automatic update feature.

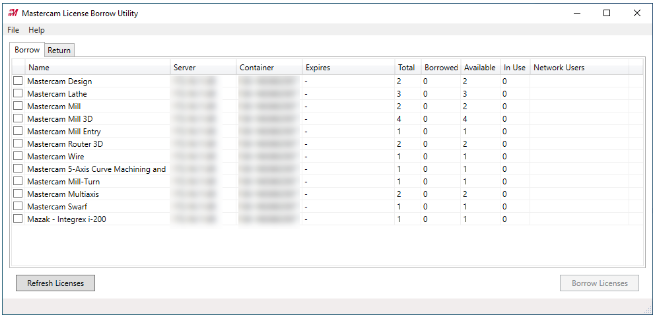

2. Borrowing Mastercam Network Licenses (General)

The Mastercam License Borrow Utility, introduced in Mastercam 2022, allows you to use your software outside of the workplace with Network Software licenses. A user can “check out” a Mastercam product license off-network for up to 10 days, to work in Mastercam outside of the office. This feature is excellent for situations where you have programmers who work outside the office for short durations.

You must be connected to the network that hosts the Mastercam licenses to borrow a license. After borrowing, you can disconnect from the network. When borrowing, you select a time frame to reserve the license. You can return the license or trade it for a different Mastercam product as needed. To streamline your workflow, you can also borrow multiple Mastercam products simultaneously.

3. New Mesh Functions and Support for Mesh Bodies (Design)

Mastercam 2022 now supports several tools for creating and modifying Mesh entities. All primitive functions can now create mesh bodies, and a large selection of tools are available to modify mesh bodies.

4. Top Level Editing for Wireframe Entities (Design)

In prior versions of Mastercam, you needed to use the Analyze function to edit the values and properties of a wireframe entity with a dialogue box. In Mastercam 2022, you can directly edit wireframe geometry without interacting with the dialog box. If no other function is active, double-click the lines, arcs, points, and splines to directly modify the entities in the graphics window with on-screen controls.

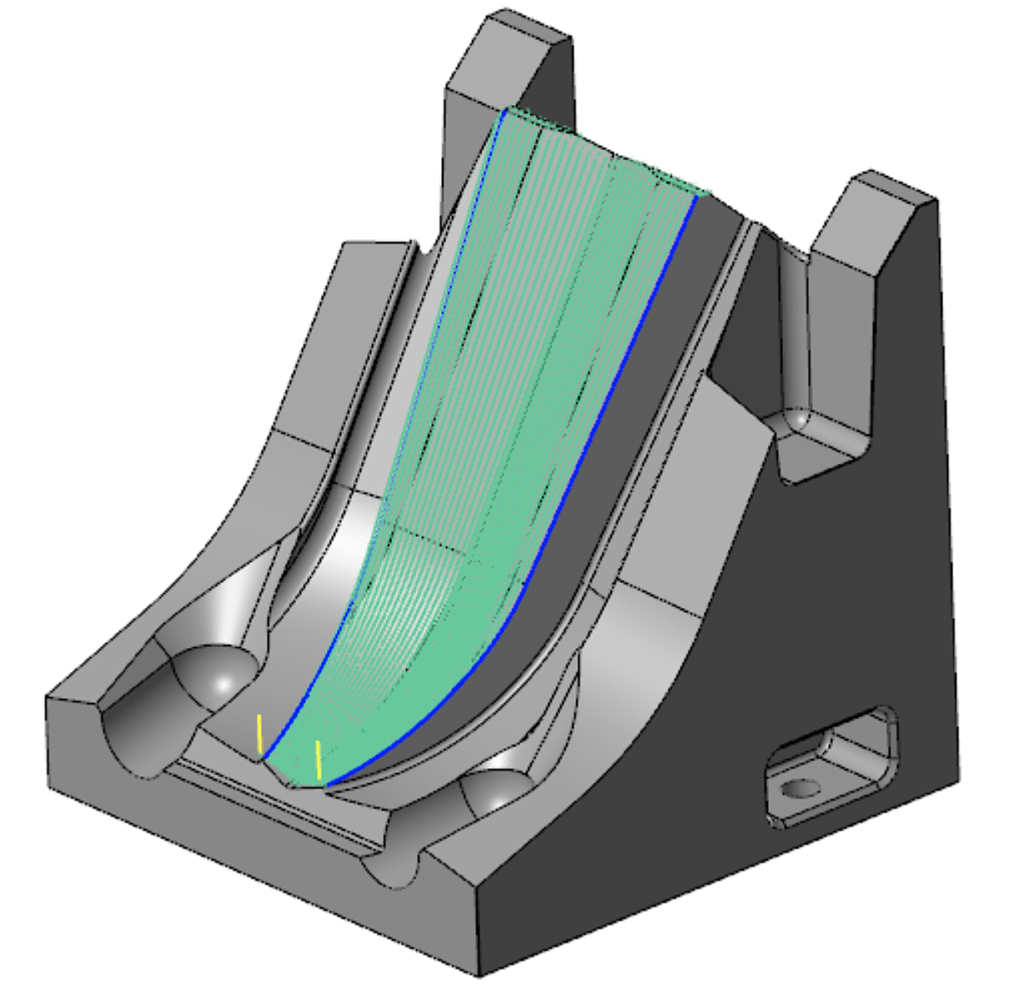

5. 3D High Speed Dynamic OptiRough Available (Mill and Router)

Previously, the Dynamic OptiRough toolpath was only available for Mill 3D. As of Mastercam 2022, OptiRough is available for Mill and Router, located in the 3D gallery in the Mill Toolpaths tab. This roughing toolpath machines very large cut depths with a bi-directional cutting strategy to remove the maximum amount of material with minimum step-downs.

The Dynamic OptiRough toolpath allows you to create a single toolpath to machine a part, instead of creating multiple 2D operations. This toolpath is collision-aware of the part and can also be aware of your tool holder by using options on the Holder page.

Mastercam 2023

Mastercam 2023 included 130 pages of updates for this version.

1. Using the Apply button with Generate Toolpath Checkbox (General)

The Apply button for tree-style milling toolpaths has been modified to be similar to the “OK” button. When you click Apply, Mastercam processes and applies your toolpath changes without closing the dialog box. If Generate toolpath is selected, your changes are applied to the toolpath, and the toolpath is automatically regenerated. If Generate toolpath is deselected, your toolpath is marked as dirty in the Toolpaths Manager to regenerate later.

2. Detecting Undercut Stock When Machining (Mill 3D)

The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions resulting in improvement to the toolpath motion and less air cutting. This new Detect undercut stock option is located on the Stock page and is only available when previous operations are set to “one other operation”.

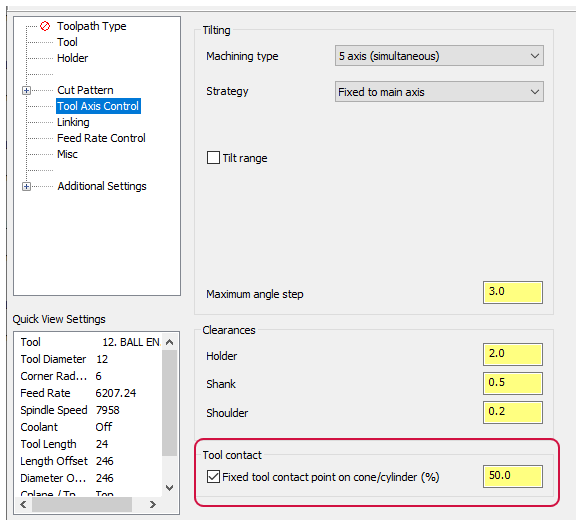

3. Deburr Control Tool Contact Point (Mill and Multiaxis)

The Deburr toolpath added a new Fixed tool contact point on cone/cylinder option in Mastercam 2023 on the Tool Axis Control page. This controls the tool’s contact point during machining. Deburr attempts to use the specified contact point, which is a percentage of the flute length of the cylindrical portion of the flute, on any supported ball, taper, or end mill tool.

4. Driving Tool Axis Control From Another Surface (Multiaxis)

The Tool Axis Control page for Multiaxis toolpaths added the Tilt relative to reference surface option in Mastercam 2023 in the Tool axis control drop-down. This option lets you drive the tool axis control from another surface, including surfaces that are shaped differently than the machining geometry. This feature is especially helpful when we have issues where our part model can cause a lot of reversals in our toolpath.

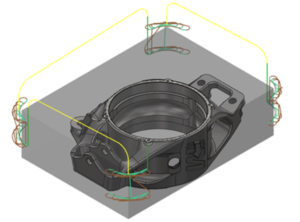

5. New B-Axis Contour Turning toolpath (Mill-Turn)

Mastercam 2023 introduced a B-Axis Contour Turning, a finishing toolpath that allows for rotation of the B-axis while the tool is cutting. This toolpath can be found in the General gallery on the Mill-Turn Turning contextual tab. The B-axis motion can be determined automatically or by using user-defined vectors to set the relative tool angle.

Mastercam 2024

Mastercam 2024 hosted 98 pages of updates.

1. The Gview Cube ( General)

The Gview Cube sits in the lower left hand corner of the graphics window, nestled inside of the gnomon used as a shortcut for Dynamic Planes. The cube has the major six faces (labeled Top, Bottom, Left, Right, Front, and Back) as well as intermediate faces between each of the major sides and on the corners as well. This not only gives us quick access to the standard plane views in Mastercam, but also new views that have not been available in previous versions. The Gview cube is very useful for general information but is also the easiest way to navigate different views without a 3D controller.

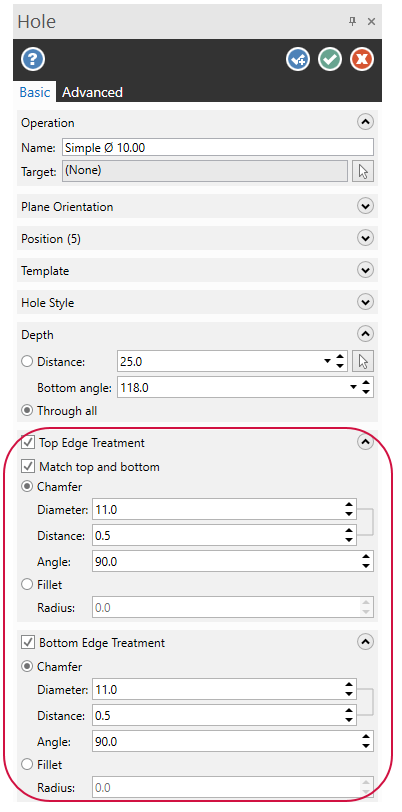

2. Solid Hole Enhancements (Design)

Mastercam 2024 now offers an easy way for you to break the hole edges in solid parts. This release added options for edge treatment from within the function panel. While in previous versions of Mastercam, you could only create a chamfer at the top edge of a hole, Mastercam 2024’s new Top Edge Treatment parameters allow you to create either chamfers or fillets on your hole edge. Mastercam has also expanded options to generate a chamfer by giving you the option to specify the size of the chamfer by entering either its diameter or its width distance. Additionally, you can now smooth the bottom edges of through holes.

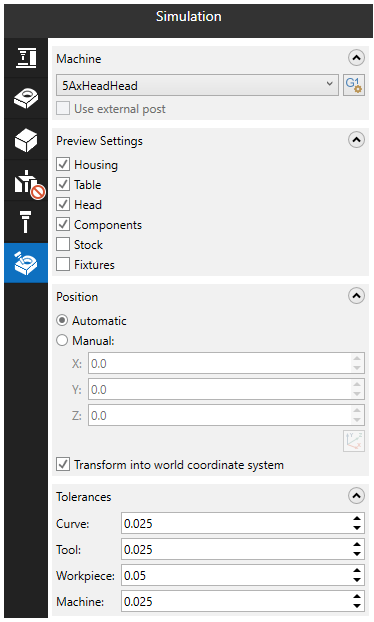

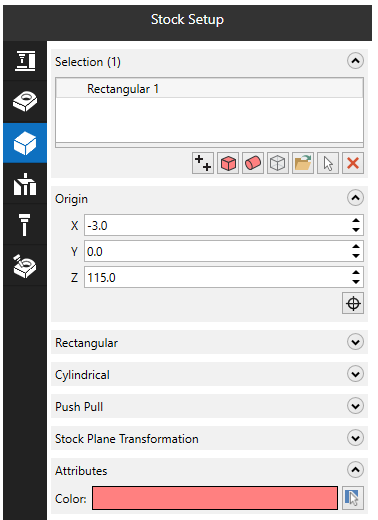

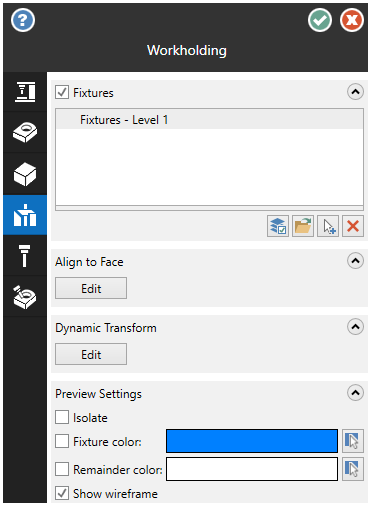

3. New Simulation Workflow and Verify Ease of Use (Mill)

Starting with Mastercam 2024, the Simulator Options are changing to help reduce redundant workflows, and provide one single location for all settings related to the active machine group and Mastercam Simulator. Mastercam Simulator now only uses the information from the Machine Group Setup panel to populate the simulation. Options previously found in the Simulation and Data tabs of Simulator Options dialog box are now located in the Simulation panel. The Simulator Options button is still available for lathe, mill-turn, and wire machine groups.

Additionally, the Verify selected machine group option in the Verify selected operations drop-down has been removed. The changes to the Simulator Options dialog box and the Machine Group Setup function panel automatically include this functionality, and it is now a redundant option.

Finally, when selecting toolpaths to send to verify if a stock model is selected as the first operation in the list, that stock model will automatically load as the starting stock for Verify.

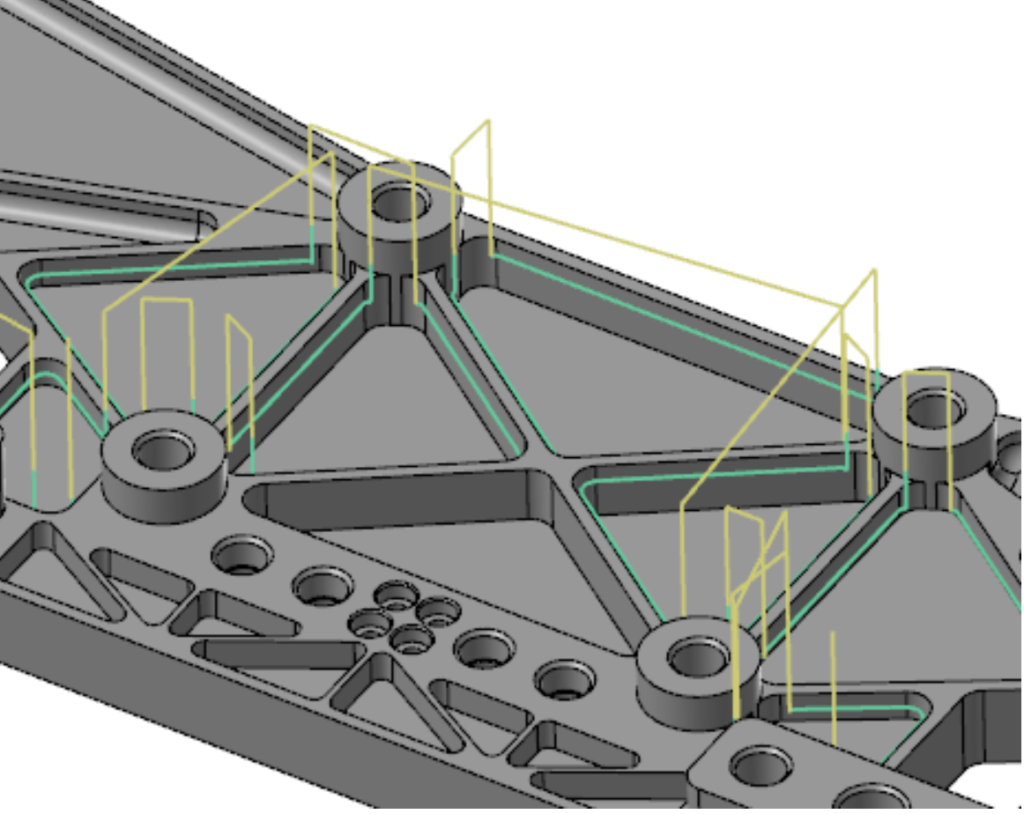

4. Process Hole (Mill)

The Process Hole toolpath applies previously defined processes to a part’s solid hole features in Mastercam 2024. A process consists of one or more hole-making operations that you build in an operations library. You can import applicable processes into the working part file when creating a Process Hole operation to make your operations quicker and repeatable. When correctly applied Process Hole can program hundreds of holes in moments.

5. Maximize Engagement (Mill)

The Dynamic Mill, Face, and Dynamic OptiRough toolpaths include a new Maximum engagement option on the Cut Parameters page in Mastercam 2024. When selected, it produces more nominal chips and minimizes the number of small chips. Additionally, Mastercam moves the tool towards the entered Stepover as quickly as possible.

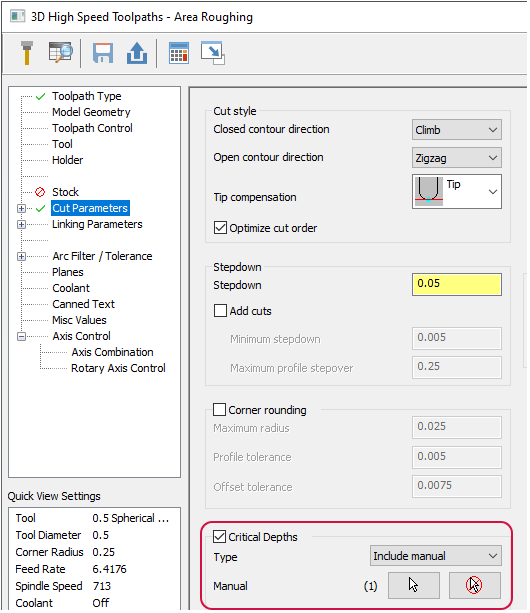

6. Critical Depths for Area Roughing ( Mill 3D)

Mastercam 2022 introduced Critical Depths to Area Roughing, which customizes how Mastercam handles flat areas when machining. In Mastercam 2024, this functionality has been expanded to the Area Roughing toolpath. With options for including all flats or only including specific depths, Area Roughing is more effective at roughing down to specific depth and reducing the need for additional floor finishing operations.

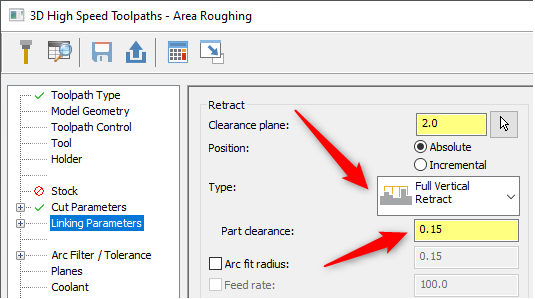

7. Minimum Part Clearance for Full Vertical Retract (Mill 3D)

Part clearance option was added for instances when the Type is set to Full vertical retract for 3D high speed toolpaths in Mastercam 2024. The part clearance sets the minimum distance the tool maintains above the part while it is machining between passes. The actual retract height is set by the Clearance plane. However, if the retract height is less than the Part clearance, Mastercam adds an additional linear move between them until the total height equals the Part clearance.

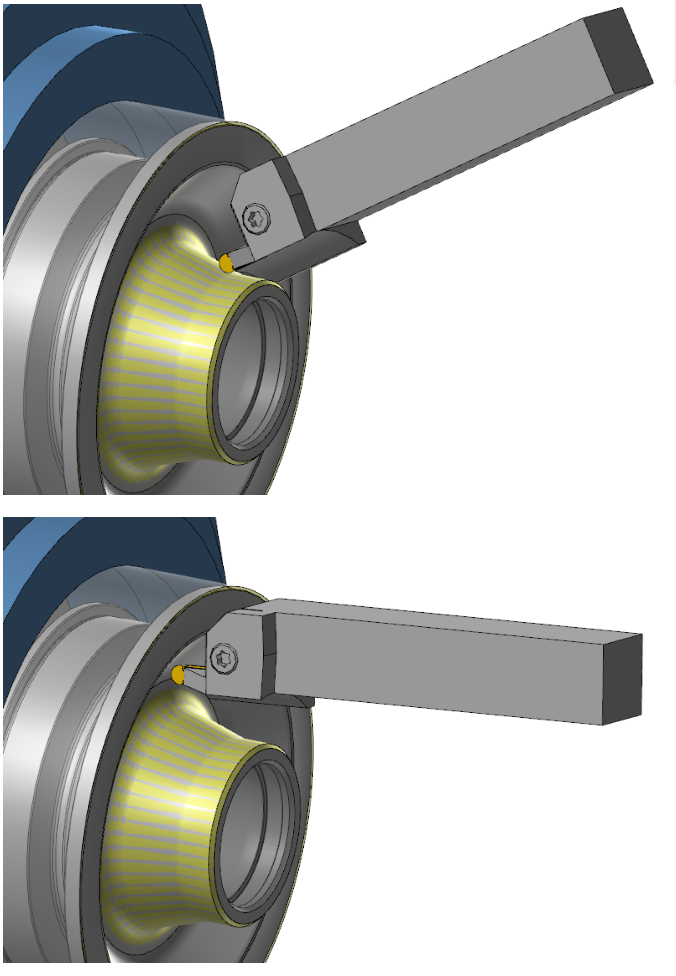

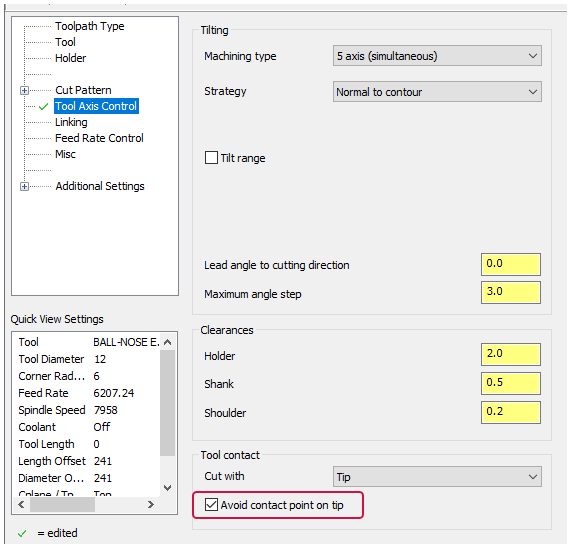

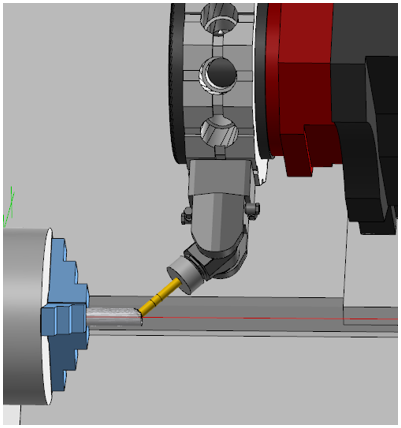

8. Deburr Enhancements (Mill and Multiaxis)

Mastercam 2024 added a new Deburr option: Avoid contact point on tip. This option angles the tool to avoid cutting with the tool’s center tip.This option is available when you set the machining type to 5 axis (simultaneous) and Cut set to Tip. Use this option to promote more even tool wear and prevent the possibility of additional burrs when cutting, such burrs can occur because of the zero SFM at the tip of the tool.

Additionally, Deburr now supports the following tools:

-

For Tip: Ball endmill, lollipop mill

-

For Flank/taper: Bull endmill, corner chamfer endmill, taper mil, dovetail tool, chamfer mill

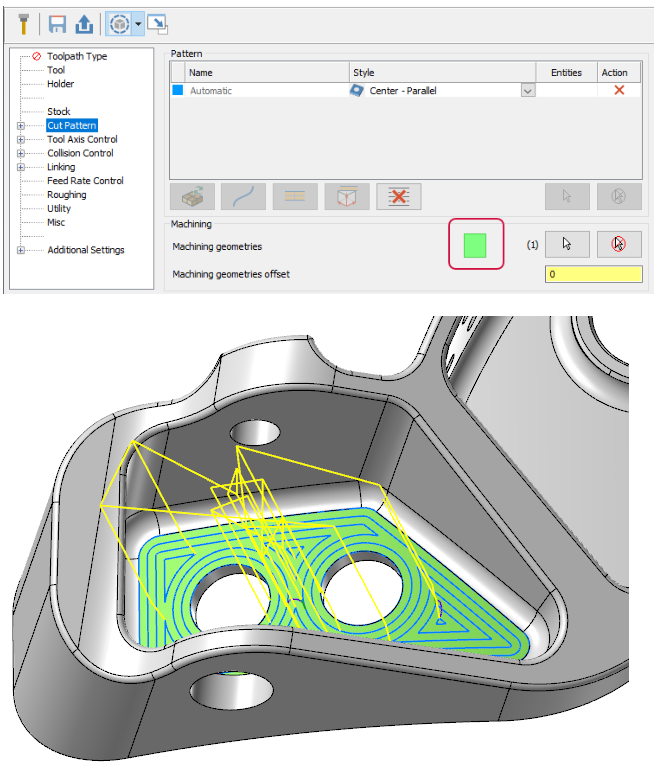

9. Setting and Viewing the Color of Selected Geometry (Mill and Multiaxis)

You can now set the color of selected geometry in the graphics window for multiaxis toolpaths within the Cut Pattern Dialog box in Mastercam 2024. The selected color remains in effect as long as you are in the dialog box. This allows us to see what is selected in the background at a glance, without having to open any selection dialogs. You can also use color with collision control groups and cut pattern rows. Change the color by clicking the color box and selecting a new color from the Colors dialog box.

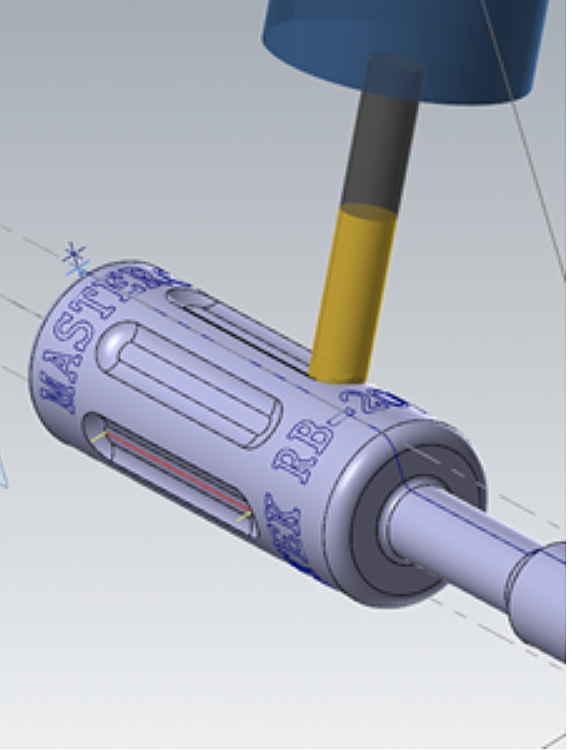

10. Turret-Mounted Angled and Aggregate Milling Heads (Mill-Turn)

Mastercam 2024 added support for turret-mounted angled milling heads in Mill-Turn. This opens up the possibility for creating toolpaths on angled planes using turret-mounted tools, vastly improving the functionality of these machines.

Follow MCAM Northwest!

Facebook: @MCAMNorthwest

LinkedIn: mcam-northwest

Twitter: @MCAM_NW

YouTube: The MCAM Northwest

Instagram: mcamnorthwest

To view and register for upcoming MCAM Northwest Mastercam webinars, visit our Events page.