- October 13, 2023

- Posted by: MCAM Northwest

- Category: Mastercam

To accurately build a Mastercam machine simulator, understanding the basics will be helpful if not essential.

What are CNC machine kinematics?

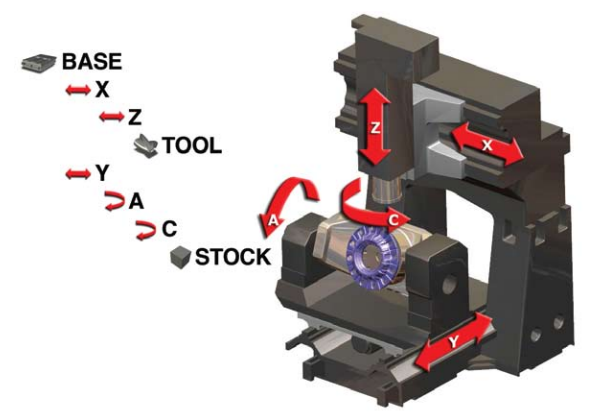

Kinematics refers to the study of motion. In the context of CNC machine simulation, it involves modeling the motion of the machine’s axes and tool movements.

Why Understanding Kinematics is so Important

Accurate kinematics are crucial when building a CNC machine simulator because they allow the simulation to accurately represent the motion of the actual machine.

By accurately modeling the kinematics of the machine, the simulation can provide a realistic representation of the machine’s behavior, including the toolpath operations and the motion of the machine itself. Having accurate kinematics in a CNC machine simulator is important for several reasons.

- First, it allows users to review the toolpaths of their program before physically machining the part, which can help detect errors and prevent costly mistakes

- Second, it allows users to set machine travel limits and detect over travels, which can help prevent damage to the machine and the part being machined

- Third, it allows users to check for any errors on the part, including machine, tool, and tool holder collisions

- Finally, it allows users to see the machine tool in action visually, which can help with part inspection and analysis

Accurate kinematics are essential when building a CNC machine simulator because they allow the simulation to accurately represent the motion of the actual machine, which can help prevent errors, detect collisions, and provide a realistic representation of the machine’s behavior.

What is The Best Way to Learn About a Specific CNC’s Kinematics?

What is The Best Way to Learn About a Specific CNC’s Kinematics?

There are several resources available that can help individuals learn about the kinematics of a specific CNC machine. Here are some steps that may be helpful:

- Consult the machine documentation: The machine documentation may have information on the kinematics of the machine, including the number of joints and the layout of the machine.

- Check the manufacturer’s website: The manufacturer’s website may have information on the kinematics of the machine, including technical specifications and diagrams.

- Look for tutorials and forums: There may be tutorials and forums available online that cover programming for the specific machine, including information on the kinematics.

- Use simulation software: Simulation software can be used to model the kinematics of the machine and test programs before running them on the actual machine.

- Consult with experts: If you have specific questions about the kinematics of a specific CNC machine, it may be helpful to consult with experts in the field, such as machine operators or CNC programmers.

Are you ready to take your manufacturing capabilities to the next level? Unlock a world of precision, efficiency, and productivity machine kinematics. See how MCAM Northwest can assist in CNC machine simulator development. Reach out to our sales team!

Key takeaways (TL;DR)

- Kinematics refers to the study of motion in the context of CNC machine simulation, involving the modeling of the machine’s axes and tool movements.

- Accurate CNC machine kinematics are crucial because they allow the simulation to accurately represent the motion of the actual machine.

- The benefits of accurate kinematics include error detection, over-travel prevention, collision checks, and visualizing the machine tool in action.

- To learn about a specific CNC machine’s kinematics, you can consult machine documentation, visit the manufacturer’s website, explore online forums and tutorials, use simulation software to model kinematics, and seek advice from industry experts.

- MCAM Northwest can assist in CNC machine simulator development.

Follow MCAM Northwest!

Facebook: @MCAMNorthwest

LinkedIn: mcam-northwest

Twitter: @MCAM_NW

YouTube: The MCAM Northwest

Instagram: mcamnorthwest

To view and register for upcoming MCAM Northwest Mastercam webinars, visit our Events page.