- March 31, 2021

- Posted by: MCAM Northwest

- Category: Insights

Connecting with your local SME chapter is key to keeping you competitive in a global market. Learn what SME can do for you and how you can get involved.

By Callie Morgan

March 31st, 2021, 3:00 PM PDT

Founded at the height of the Great Depression in Detroit, Michigan, The Society of Manufacturing Engineers (SME) has grown to an international organization with local chapters in 72 countries. You may know them for their involvement in popular events such as Westec, Eastec, AeroDEF, Fabtec, etc.

Chris Hehman, a member of MCAM’s Sales Team, joined SME back in 2019, after chatting with the local chapter at one of our Live events at Lane Community College.

“I realized that it could be a good way to gain better connections in the Manufacturing Community in Oregon, especially after having been away from the State for so many years,” Hehman said, “and, also, increase communications and the flow of ideas and the flow of ideas between manufacturers around the State.”

The overarching goal of SME is to improve manufacturing worldwide by establishing connections with local manufacturing communities, by building professional relationships with industry professionals and students at trade schools. At the local level, chapters can set their own goals. Willamette Valley Chapter 423’s vision is to “Enhance progress, prosperity, and strong communities through manufacturing in the Willamette Valley and beyond.” As SME’s only professional chapter in the state of Oregon, Hehman serves as the Chair for Chapter 423. Hehman’s personal goals within the chapter are to further promote continuing education and the growth and spread of intelligent manufacturing practices and keep manufacturing.

“Life and the accumulation of knowledge move forward; you just have to work at it,” Hehman explains.

SME stresses the importance on being involved with the local community. SME officers are heavily involved with local student outreach programs throughout the year, such as robotics competitions, graduation ceremonies, mock interviews and bringing student groups to local trade shows. SME also offers research assistance, Scholarships, training certification opportunities, job finding assistance, access to a growing network of manufacturing professionals, and much more.

There is an industry professional mentorship program students can sign up for by becoming a member of SME. Students in SME should contact their local chapter to get connected with a mentor that is involved in what they are interested in doing professionally. Industry professionals must pass a background check to be selected as a mentor. For more information on how to apply to the mentorship program, visit the SME Mentorship page.

In his 30+ years in the manufacturing industry, Hehman has witnessed the move from drafting tables to CAD and CAM programs and 3D printing. With all the great technological advancements made within manufacturing in the past 10 years, Hehman sees one issue that remains constant: many businesses are so deeply rooted in their methods and refuse to evolve, even though it costs them.

“You will hear the statement a lot: ‘We’ve been doing it this way for many years’. Nothing would make me happier than to be able to reply and say, ‘well, that consistency could be a problem, why don’t we look at it and see if there are newer methods?’” Hehman said.

Although making a product in a way that is reliable and consistent in quality is important, it is typically not ideal if many decades could go by with a shop using the same process.

“Can you imagine going to a doctor or dentist that was doing things the same way his grandfather did? Or can you imagine using the same computer or gaming system your grandfather (or I) did?” Hehman jests. “That would be a PITFALL.”

The key benefit of companies being involved in SME is the access to knowledge that keeps your shop modern and competitive. SME offers continuing education and certification courses for professionals.

“If there are better ways of doing things, it should always be your job to find and implement them.” Hehman stresses.

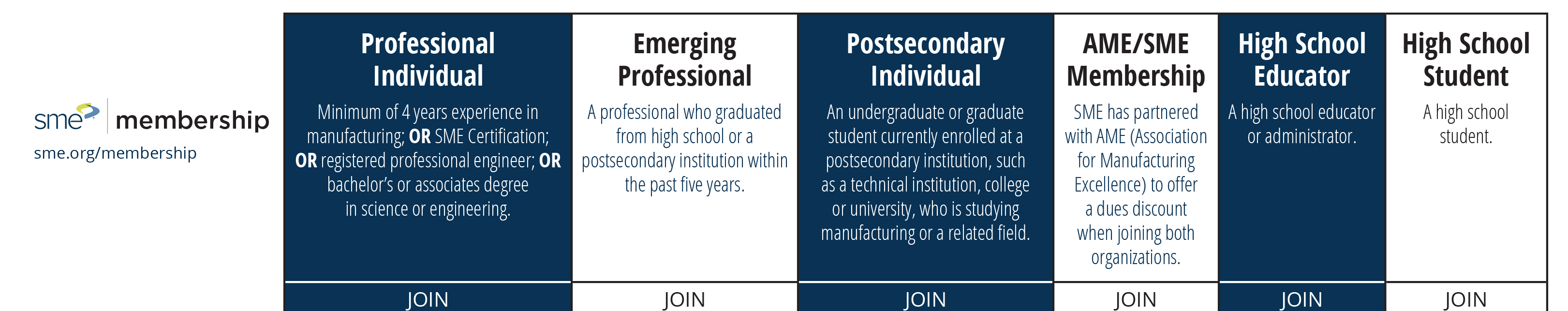

Are you ready to connect with the local manufacturing community and current industry knowledge resources? There are many ways to get involved with your local SME chapter, whether you are joining for personal growth or for business.

1. Contact your local chapter representatives

You can find the organization closest to you, both in the US as well as globally, at the following link. Clicking on a location will show you both the professional as well as student chapters in your area: https://www.sme.org/sme-membership/chapters/. For professionals in Oregon, visit https://connect.sme.org/communities/home/66 or contact Chris Hehman directly at chrish@mcamnw.com.

2. Offer tours or virtual tours to the SME group.

Tours can be at any level you want, but don’t show anything confidential. Tours are a way to share information and get ideas from both a local and national perspective. These tours are often attended by members from students all the way to the retired, and every stage in between.

“You can think of [SME shop tours] as allowing the rising tide (of information related to methods of manufacturing) to come in and lift all the boats (individual manufacturers),” said Hehman. “It can also be seen as a way for students to talk to their potential future employers.”

3. Companies can encourage their employees to be involved in SME, and give them the time to do so.

The more involved your employees are, the more benefits you should see.

“Employees will be exposed to a wider range of ideas and methods, from which, they will pull in things that will help their company”, adds Hehman.

4. Sponsor local schools.

Get schools interested in your company and what you do. Help the schools show their students, who could be you possible future employees, just how rewarding a career in manufacturing can be.

Follow MCAM Northwest!

Facebook: @MCAMNorthwest

LinkedIn: mcam-northwest

Twitter: @MCAM_NW

YouTube: The MCAM Northwest

To view and register for upcoming MCAM Northwest Mastercam webinars, visit our Events page.