- February 28, 2022

- Posted by: MCAM Northwest

- Categories: Insights, Mastercam

What is considered a legacy post? Why should I choose a custom post over a free generic post? We answer all these questions and more!

By Callie Morgan

Monday, February 28th, 2022, 10:00 AM PST

What is a Post Processor?

A post-processor (known as a “post”) translates toolpath data from your CAD/CAM software to a language that your specific CNC machine can understand. If you think of a post like driving a car, the CNC machine is the car and the post is the wiring between the pedals, steering wheel and other driving components that make the car drivable.

Picking the right kind of post for your machine is a crucial part of the machining process. Your choice of post can impact not only your machine’s ability to operate, but its ability to access its full potential. Let’s put the pedal to the metal and help you decide which post will drive your machine the most efficiently, and leave your competition in the dust!

Legacy Posts

So, when do you know if it’s time to update your older post to a more modern post? We define a legacy post as a generic or custom post that was written for Mastercam version X9 (2015) or earlier. We have seen some legacy posts that are so old that they aren’t capable of processing most modern Mastercam toolpaths.

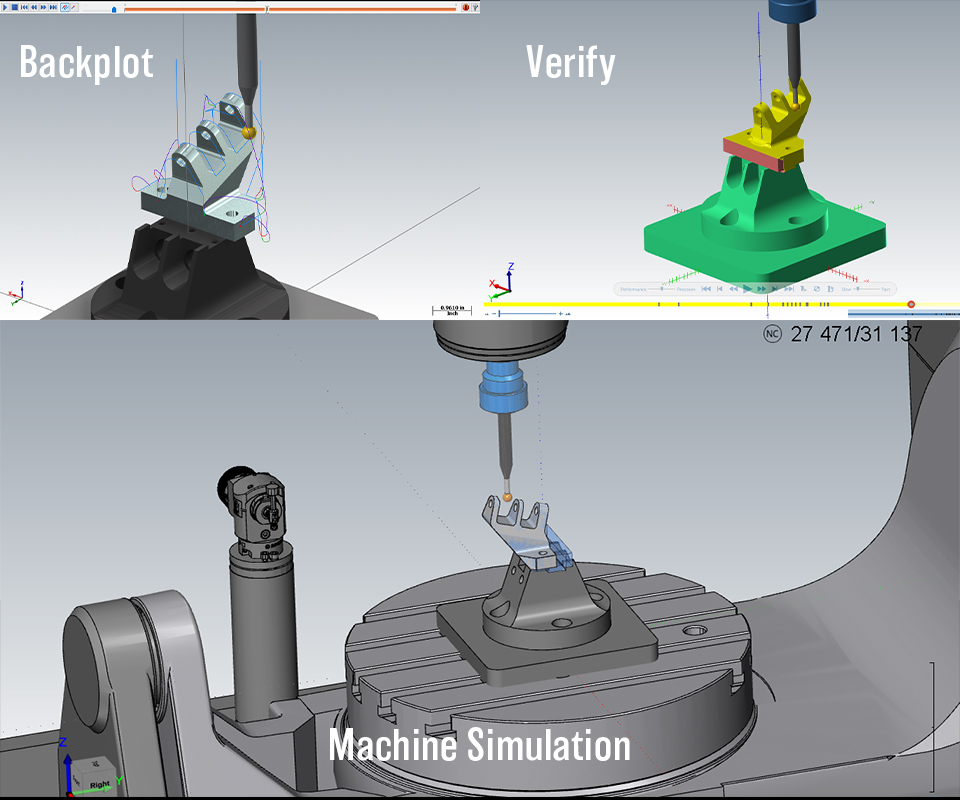

Aside from being able to use more advanced toolpaths, a few other reasons it would be profitable to switch to a modern post is if you want to add machine probing, .machine simulation, or your machine has firmware updates that make your existing post not work correctly. An important thing to note is that legacy posts will never be able to connect to .machine simulation. Having simulation with a post is a huge advantage of having a modern post.

When updating a post, the existing post is either migrated to a newer format or an entirely new post is written. Migrating a post brings forward the functionality of the old post, but it may not support all features in the current version of Mastercam.

Generic Posts Vs. Custom Posts

Let’s continue with another car analogy. Let’s say you have a 2010 Ford Mustang GT Coupe. A generic post would only include what is factory standard for a 2010 Mustang GT Coupe. It would not include if your engine has a supercharger, has lowered suspension, has Grabber Blue color paint, has high-performance tires, or other customizations. A custom post, however, would include all those extra features that you purchased for your machine.

Generic posts are available for free on the Mastercam Tech Exchange and are recommended for machines with 3-axes or less. Generic posts are editable to a certain degree, as they are written in an open language (MP Post Language) and can be modified by any end-user who understands the language. Necessary documentation is available for your machine from your reseller, so you can edit the generic post to your liking. However, editing a post is quite a time-consuming undertaking.

The “free” and editable aspects of generic posts make them seem like a good option. However, there are a couple of things about generic posts that you should be aware of before using them.

Understanding whether you need a generic or a custom post requires understanding what your machine’s capabilities are. A generic post doesn’t fit all machines. The header at the top of the post will describe the capabilities of the post, so you can see if it matches your machine’s capabilities. However, in most cases, you have to test out a generic post to find out if it actually works for your machine.

If you discover that the generic post does not work for your machine, the post will need to be modified. It is important to note that generic posts are limited on what can be modified until they are considered custom posts. Modifications of generic posts are limited to cosmetic fixes, such as N-numbers on every line vs. only at the start of every toolpath operation, G02 vs G2, truncating number of decimal places display 1.2345 vs 1.234, etc.

However, in most cases, modifying a generic or legacy post is more expensive than ordering a new, custom post.

A custom post is written to be a digital twin to your machine and will include all the individual upgrades and features that you purchased for your particular machine. It can also contain customization for documentation that is specific to your company’s procedures.

With custom posts, you have a lot more freedom for what features can be added. Some examples are adding high-speed milling codes, dynamic work offsets, probing, and tool center point control. The post writers handle all the writing of the custom post for you, provided that you have a current post maintenance contract with us. MCAM Northwest’s custom Mastercam posts are written by our northern neighbors at Postability, a trusted Mastercam partner.

When you do purchase a custom post, there is an opportunity to get a lot more out of your purchase with the Custom Post + Machine Simulation Bundle, which you can read more about here. This bundle is recommended for 5-axis mills and 4-axis mills.

Mill-Turn .machine Environment and Mill-Turn Lathe Environments are a recommended post add-on for anyone with live tooling lathe with a Y-axis and required for multi-stream machines or lathes with B-axis heads.

Picking the right post-processor for your machine is a big decision, and we are happy to help you make the right choice that works for the type of programming you do. If you are interested in getting a new custom Mastercam post or modifying your current Mastercam post, visit our webpage for our Post Modification form and Custom Post Request forms and reach out to our Sales Team at (503) 653-5332 or sales@mcamnw.com.

Follow MCAM Northwest!

Facebook: @MCAMNorthwest

LinkedIn: mcam-northwest

Twitter: @MCAM_NW

YouTube: The MCAM Northwest

To view and register for upcoming MCAM Northwest Mastercam webinars, visit our Events page.